The need for a partner to co-develop and ensure design for manufacturing for high volume production layed the foundation for the partnership between Abena and Mekoprint.

Abena have been manufacturing incontinence products and diapers since the 1970s. Together with Silicon Valley based MediSens Wireless, Abena created the world’s first digital incontinence product using wearable technology. Abena developed the incontinence product and MediSens Wireless the IT cloud solution. Mekoprint was chosen to develop and produce the printed stretchable sensor linking the two solutions together.

Abena have been manufacturing incontinence products and diapers since the 1970s. Together with Silicon Valley based MediSens Wireless, Abena created the world’s first digital incontinence product using wearable technology. Abena developed the incontinence product and MediSens Wireless the IT cloud solution. Mekoprint was chosen to develop and produce the printed stretchable sensor linking the two solutions together.

The solution Abena Nova is the world’s first intelligent incontinence solution produced for everyday use. A disposable product with built-in sensor and a small discrete clip attached. The sensor register when the product is wet and a notification is sent to the caregivers’ smartphones or tablets.

Director and owner of ABENA

Arne Terp-Nielsen

Scale to cost-effective mass production

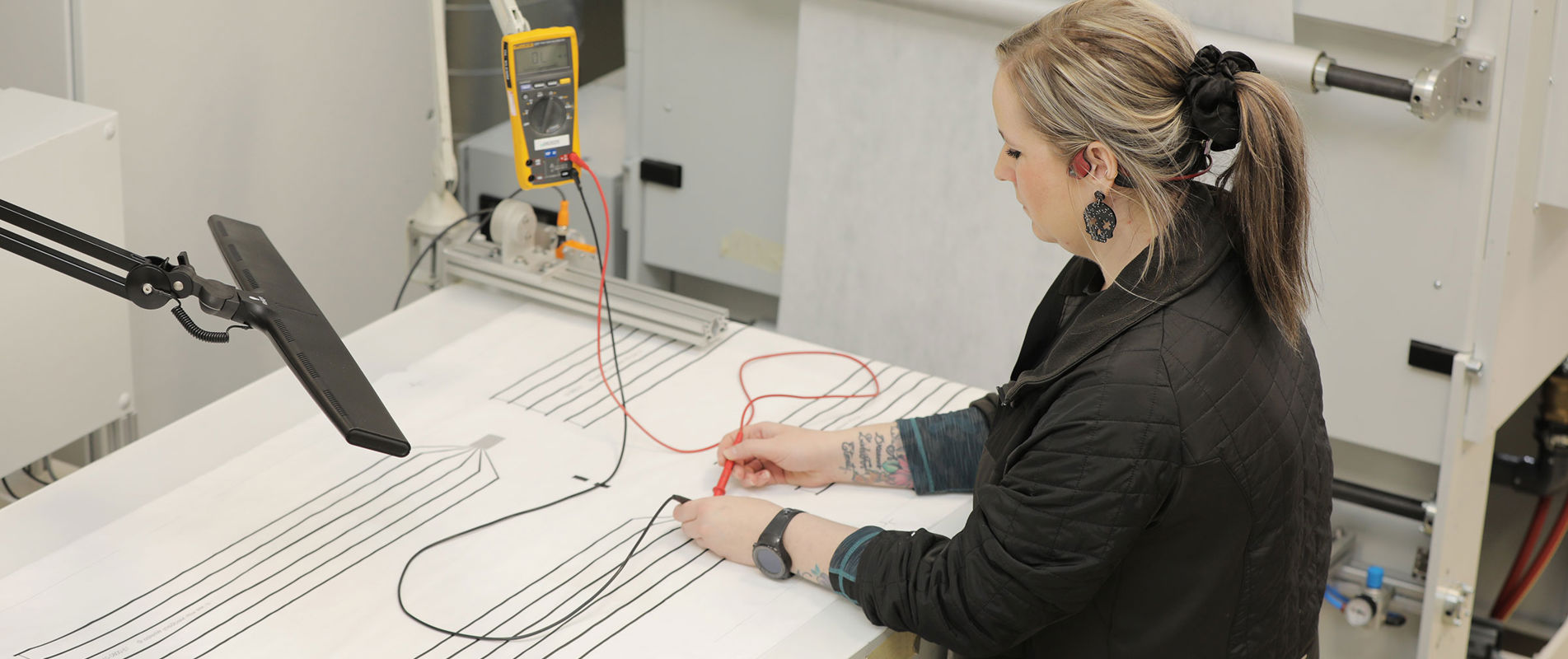

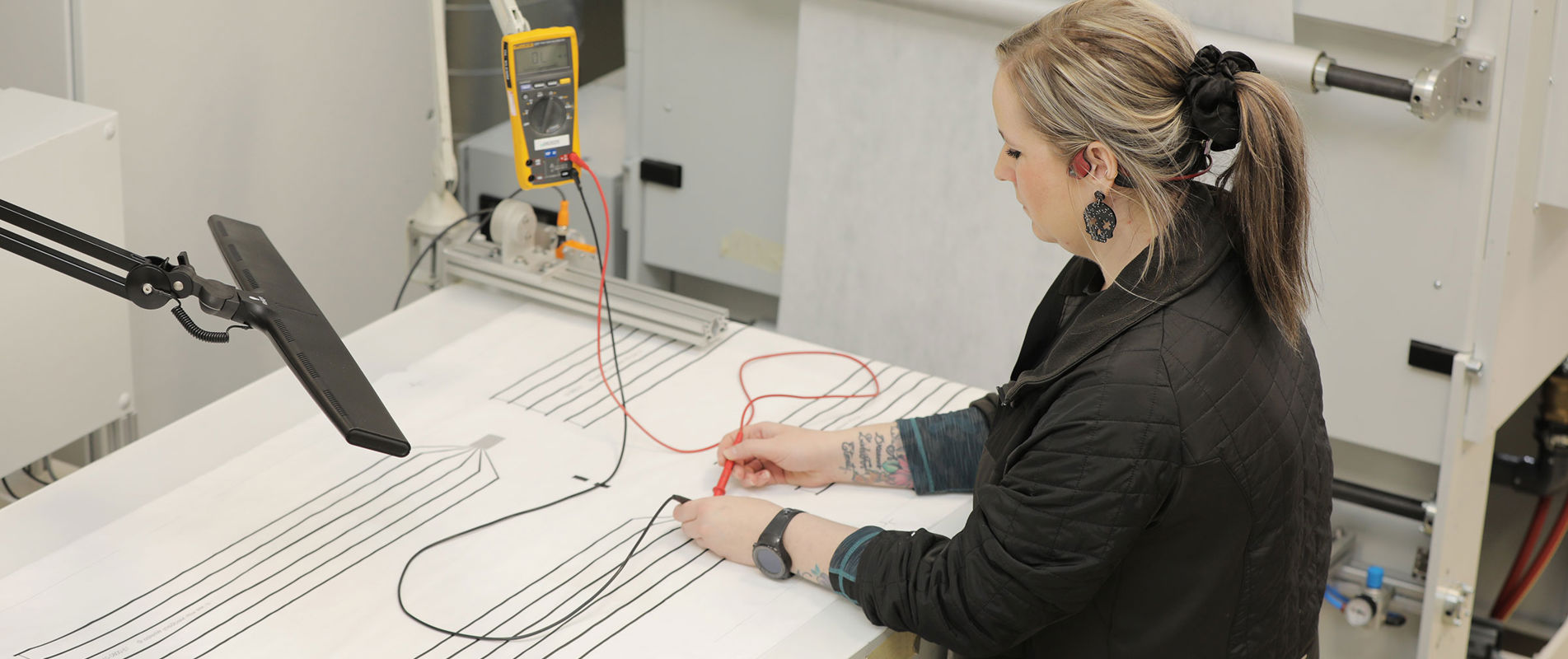

As a leading European supplier of screen printed electronics, Mekoprint had the in house competences to drive the development project and ability to scale to cost-effective mass production in high volumes, matching the global ambitions for the product.

Mutual investments for global ambitions

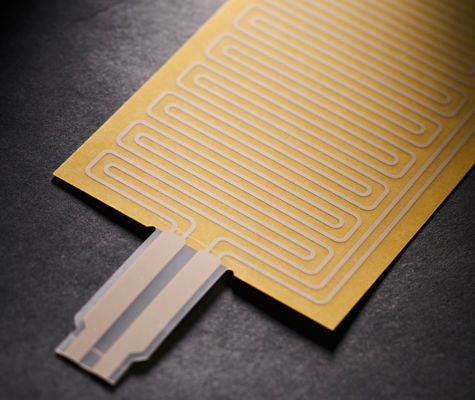

The sensors are made with an ultra-thin, soft and stretchable non-woven material screen printed with conductive carbon and laser cut into right dimensions.

Without creasing, breaking, stretching or shrinking the material, the entire production are handled in a fully automated roll-2-roll production setup with minimum manual handling. An optimum solution for printing electronics on extremely thin stretchable foils – a solution that is both cost efficient and scalable for high volume production.

Managing director, Abena Produktion

Arne Terp-Nielsen

CEO, Mekoprint

Anders Kold

Download free lookbook

Get in touch with us

-

Ultra-thin wearable sensors ideal for single-use health care applications. Brings electronics close to the body.Wearable sensors

Ultra-thin wearable sensors ideal for single-use health care applications. Brings electronics close to the body.Wearable sensors -

Lightweight and thin printed heaters. Flexible structure, easy to integrate and tailored to any shape and size.Printed heaters

Lightweight and thin printed heaters. Flexible structure, easy to integrate and tailored to any shape and size.Printed heaters -

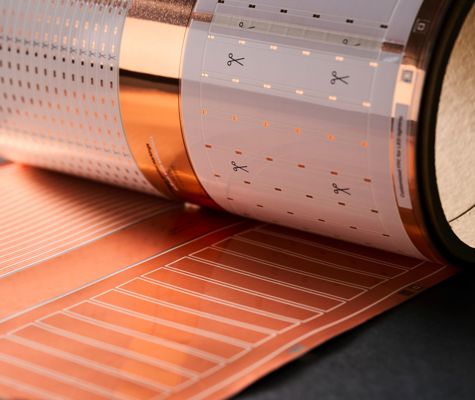

Flexible circuits cut down on space and weight. Ideal for devices where a rigid circuit board will be impractical.Flexible circuits

Flexible circuits cut down on space and weight. Ideal for devices where a rigid circuit board will be impractical.Flexible circuits