The project involved:

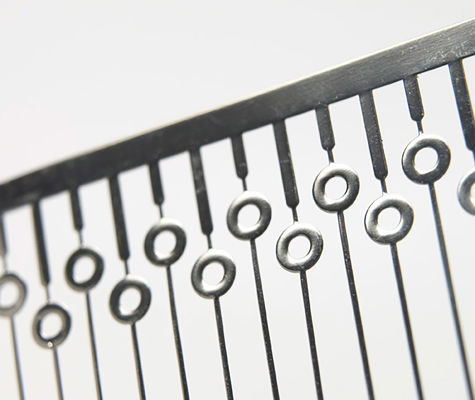

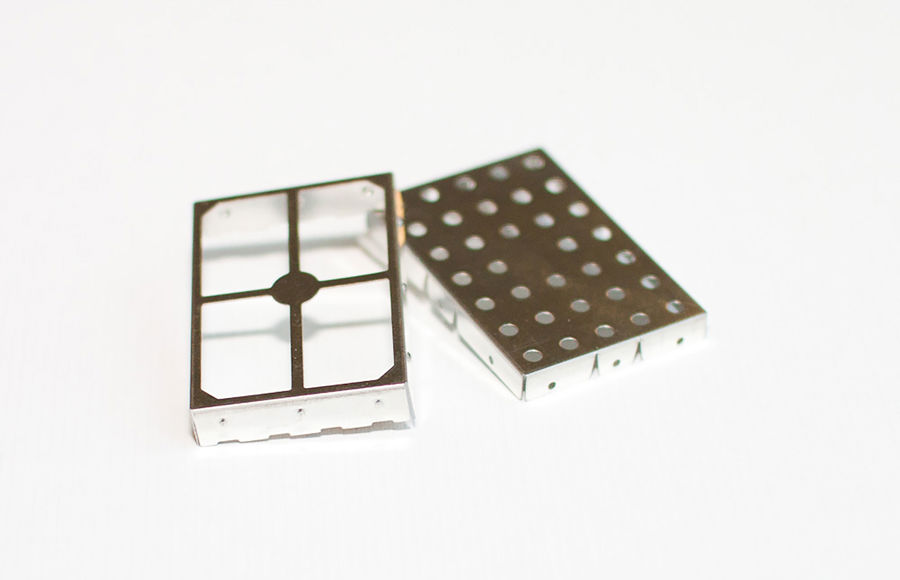

- Efficient volume production of two EMI-shields with a material thickness of 0,3 mm

- 100 % panel inspection to ensure zero-tolerance for defects

- Transportation and further processing at Necas before final delivery to the customer

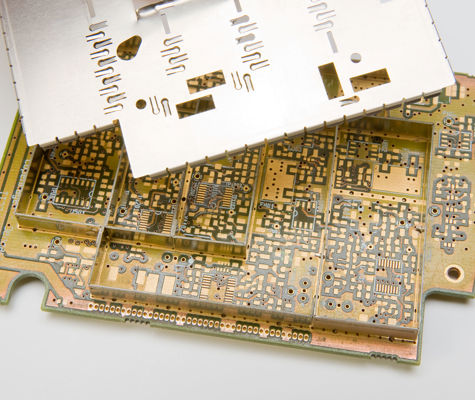

For several years, Mekoprint has partnered with Necas, a full-service provider of EMS (Electronic Manufacturing Services) solutions, to produce and deliver customized EMI solutions for a shared customer in an advanced industry.

The quality of the components has improved significantly. The impact of our collaboration means that the components can now be machine-assembled, reducing subsequent processing time for inspection and rework by up to 90%

CTO at Necas

Allan Sigfredsen

Our collaboration with Mekoprint has been constructive because both parties focused on the details. The optimization saves our operators from parts of the manual assembly process, allowing them to focus on monitoring the machines.

CTO at Necas

Allan Sigfredsen

The trial with the new packaging has inspired us to expand the concept to more customers. It opens new opportunities for cost reduction, securing quality during delivery, and increasing the use of biodegradable packaging – all with the goal of providing the best service for our customers and maintaining an open and strong dialogue with partners like Necas

Area Sales Manager, Mekoprint Micromechanics

Henrik Groes

Related solutions

-

A closed EMI shielding is the ideal solution for protecting electronic components from electromagnetic interference.Closed EMI Shielding

A closed EMI shielding is the ideal solution for protecting electronic components from electromagnetic interference.Closed EMI Shielding -

Explore the wide variety of micro component solutions tailored to your needs.Precision Micro Components

Explore the wide variety of micro component solutions tailored to your needs.Precision Micro Components -

Customized EMI shielding solutions that cater to your exact needs.Customized EMI-solutions

Customized EMI shielding solutions that cater to your exact needs.Customized EMI-solutions