When sourcing cable assembly and wire harness solutions, European sourcing, scalable production, and low PPM are key.

We specialise in high-quality cables assembly tailored to your specific requirements. With many years of experience within cable assembly, we support leading industries across Europe who require efficient and reliable solutions.

Offering assembly in accordance with your specifications for a wide variety of wires, cables, connectors, terminals, and contacts.

Always striving to minimise the costs throughout your supply chain - including a broad range of cables and connectors for optimal development and assembly. We are at our very best if you require small to medium-volume.

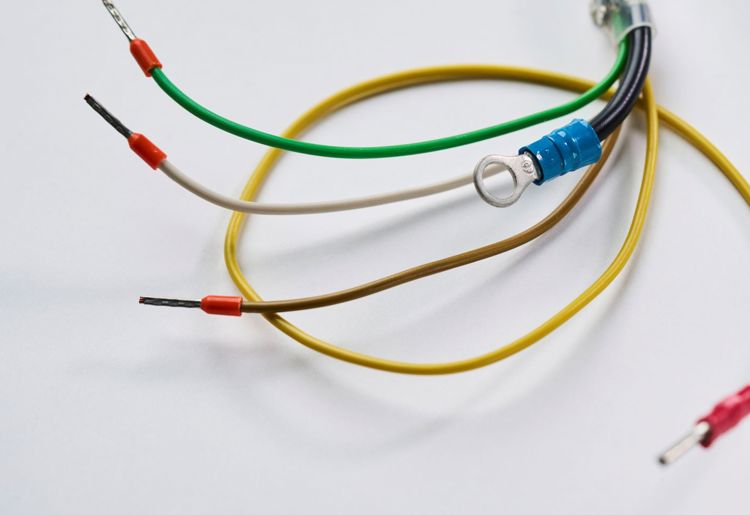

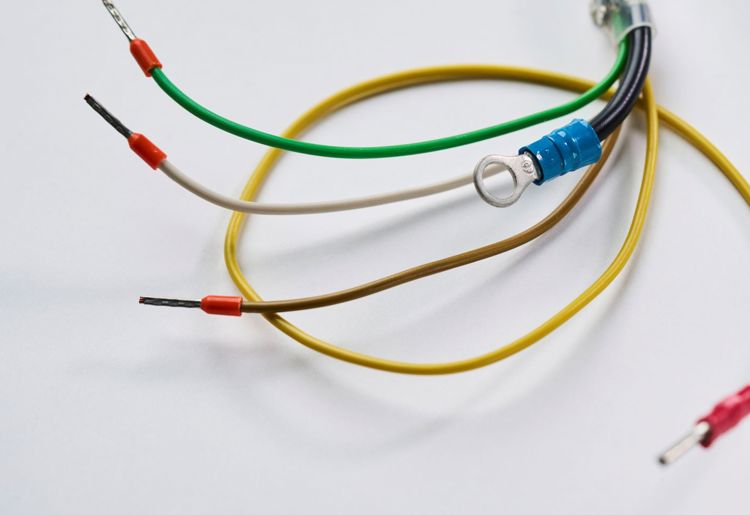

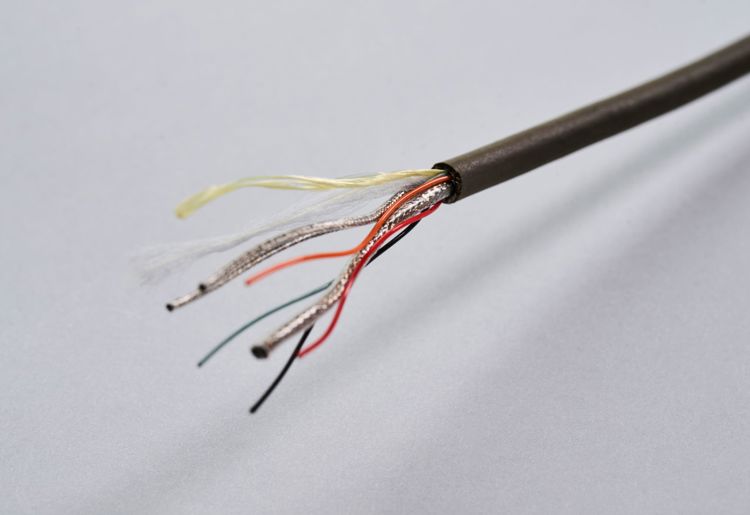

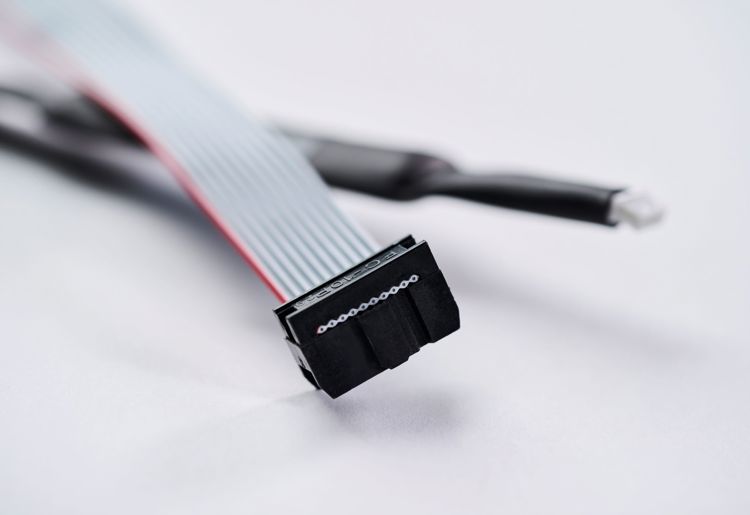

Types of cable assemblies & wire harness

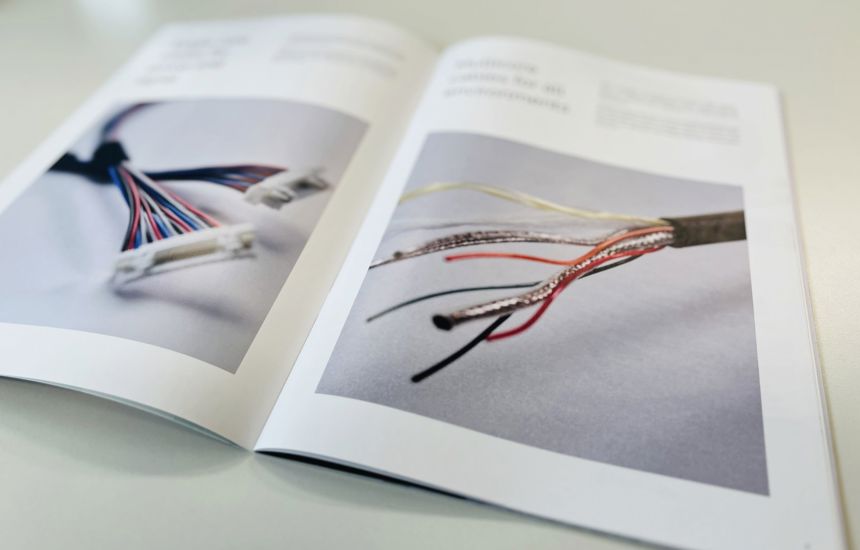

Each cables assembly is produced in accordance with customer specifications, using high-quality connectors, terminals, and contacts - with a variety of finishing methods.

.

-

Ideal for use in control and distribution panels, light fixtures, and other electronics. Available with or without terminals and labelling for easy integration into your products or wiring harnesses.

-

With multiple insulated conductors bundled together, the cables offer enhanced efficiency and space-saving benefits, making them essential in a wide range of applications.

-

A wiring harness is known as a organised set of wires, terminals and connectors, connecting the complete or part of a machine, engine, vehicle or other electronic device requiring efficient power and signal flow.

Whether it's a simple setup with a few wires or a complex system with hundreds of connections, our wiring harness solutions cover all needs.

-

Designed for high electrical currents and mechanical stress, heavy cables are typically constructed with thick insulation and conductors to handle heavy loads and harsh environments.

-

Coax and RF cables for transmitting high-frequency signals engineered with low-loss dielectric materials for precise and reliable performance in your application.

-

Multiple conductors arranged parallelled side by side in a flat, ribbon-like configuration. These cables provide space efficiency, flexibility, and ease of installation, making them suitable for various applications across industries.

-

Molded connectors, housings, or overmolds tailored to meet specific performance and durability requirements in different environments. The benefits includes optimum protection, better tactility, easy installation and option of branding with embedded logo.

-

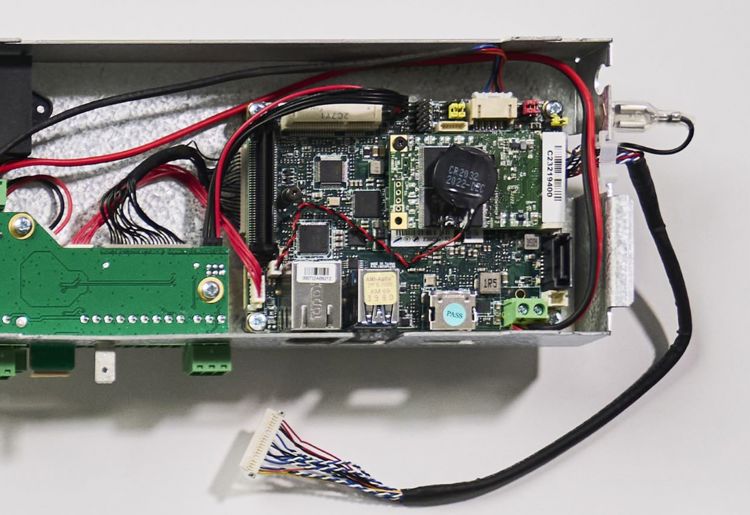

Receive a more complete ready-to-use component. Let us integrate your cables with other components like metal chassis, plastic enclosures, power supplies, various types of electrical shielding, etc.

-

Leverage our extensive experience in taking over in-house production and assembly of pre-harnessed cables. With a track record of successful projects together with industry leaders, we are ready to assist you.

Get in touch with us

Behind the scenes of cables assembly & wire harness manufacturing

-

In a price-sensitive market, we know that early advice from our engineering team can be beneficial for future production. Technical advice includes material alternatives, performance assessment, pricing, lead time, etc. so your cable component is customised for both product and production.

We aim to challenge you early in the design process to ensure cost efficiency throughout the entire manufacturing process and product lifetime.

For us, a cable is not just a cable, so ask for our advice. We will gladly share it, because our aim is the same as yours - to work for you, together with you.

-

Our harness solutions are made at our factories in Poland and Ukraine. Here more than 200 skilled employees are involved in production. They ensure competitive prices without compromising on quality or delivery.

Our sales teams are based in both Denmark and Sweden.

-

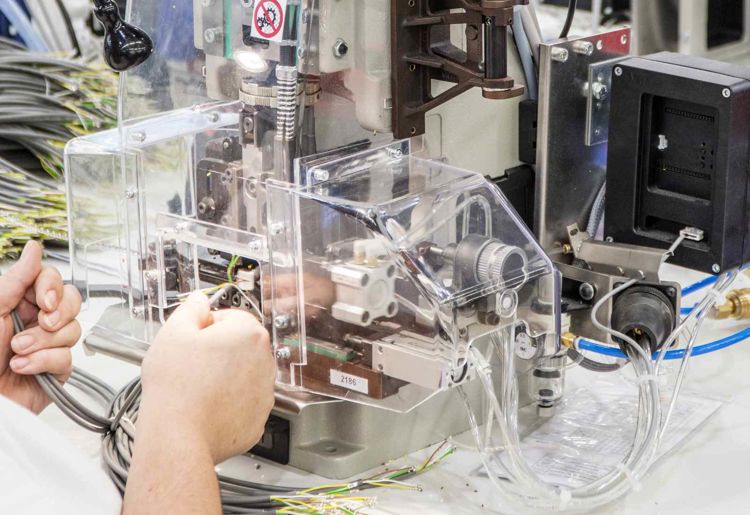

We are proud to present our local European production facilities that operate with a high level of automation, modern technology, and skilled workers. They demonstrate high level of flexibility and efficiency in independent teams and production flows with distinctive core competences.

You can rely on us to always aim to deliver leading quality solutions with lean production and short lead times.

-

We are proud to offer a full range of services to meet all your cable assembly requirements. With state-of-the-art machinery and know-how, we handle everything from cutting and mounting to coiling and labelling, covering a wide variety of cables.

Dedicated to maintaining a leading position of technology, we constantly invest in highly automated production equipment, allowing us to handle cable assemblies in both high and low volumes.- Semi-automated crimp

- Automated crimp to crimp process, with optional isolation printing, in wire gauge AWG10 to 28

- Fully automated production process cut, strip, crimp and housing insertion wire gauge AWG22 to 30

- Electrical testing with the option to add push back technology

- Manufacturing according IPC/WHMA A-620

- Printing or marking of connector housing or other materials

-

We like to say we create strong connections! Always based on good craftmanship.

Our commitment to quality is highlighted by our ISO 9001, 14001, and 45001 certifications, along with adherence to IPC/WHMA-620 standards.

With our own certified trainer ensuring that our fitters are constantly updated and skilled, we maintain a continuous quality-focused approach to production - always aiming to be your preferred partner in cable and wiring assemblies.

We of cause provide requested documentation such as Production Part Approval Process (PPAP), First Article Inspection Report (FAIR), and Part Submission Warrant (PSW).

-

We recognise that time is a limited resource in any project. That is why we strive to provide short lead times for both prototypes and serial production.

With highly adaptable production facilities in Poland and Ukraine, we can quickly use available production capacity. We can also offer dual sourcing by activating both factories simultaneously.

As a guideline, you can expect a lead time of two weeks on prototypes if we have the selected materials in stock. Series production will be either made to order or made to stock, depending on the logistics solutions customised your needs.

Please contact our sales team to discuss the solution that suits you best.

Download free lookbook

Quality, certifications and compliance

Our dedicated and ongoing focus on quality systems, environmental, and working environment standards is reflected in the certifications achieved by our facilities in Poland and Ukraine. Our processes are structured in accordance with ISO 9001, ISO 14001, and ISO 45001, certified by Dekra.

Click here to learn more about the management systems of Mekoprint.

From idea to finished component

-

We begin by identifying and selecting the best materials - like connector systems, wires, and other components - that meet the specific needs of your product and comply with industry standards. Early involvement helps us reduce supply chain risks and improve cost efficiency.

-

Our skilled engineering team focuses on designing products that are easy to manufacture and integrate. We ensure the designs are assembly-friendly, manufacturable, and meet all necessary industry standards and regulations.

-

We document the manufacturing process, including specifications, procedures, and quality standards, to ensure consistency, traceability, and compliance.

-

Samples and prototypes are produced and tested to confirm cable design and construction, manufacturing process, and performance of the cables.

Our production and testing facilities allow for rapid iteration, problem identification, and design refinement to enhance functionality and usability.

-

We manage the customer approval process, using First Article Inspection Reports (FAIR), Production Part Approval Process (PPAP), or other quality assurance protocols, to prove the product's compliance and readiness for production.

-

After receiving customer approval, we move forward with volume production, managing manufacturing processes, procurement, and resource allocation to adhere to production schedules and delivery timelines.

-

Logistic agreements are crucial for managing the supply chain, ensuring efficient transportation, and the timely delivery of materials and finished products.