Download HMI lookbook

Define your assembly

A keypad mounted on a backplate is one of the most common and efficient HMI configurations. It enables fast and easy mechanical integration at your end.

The keypad is typically a membrane switch or silicone rubber type, mounted on a metal or plastic backplate – adapted to your product and assembly process.

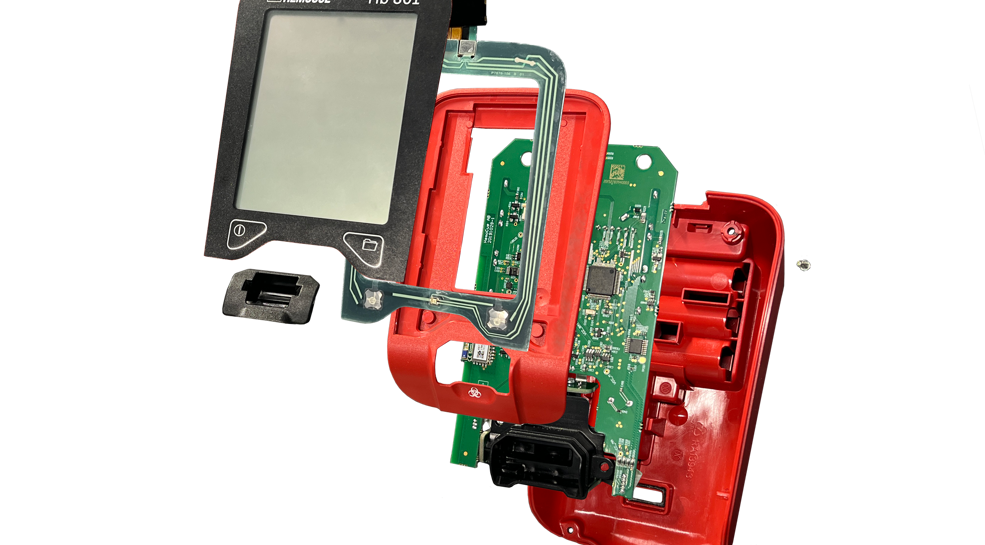

A more advanced solution with multiple functional layers built directly into the keypad construction – such as EMC shielding, light blocks or environmental sealing. These assemblies are typically delivered mounted on a housing, allowing effortless integration into your product.

The construction can be tailored to demanding environments or specialised use cases where reliability, sealing or controlled light behaviour are critical.

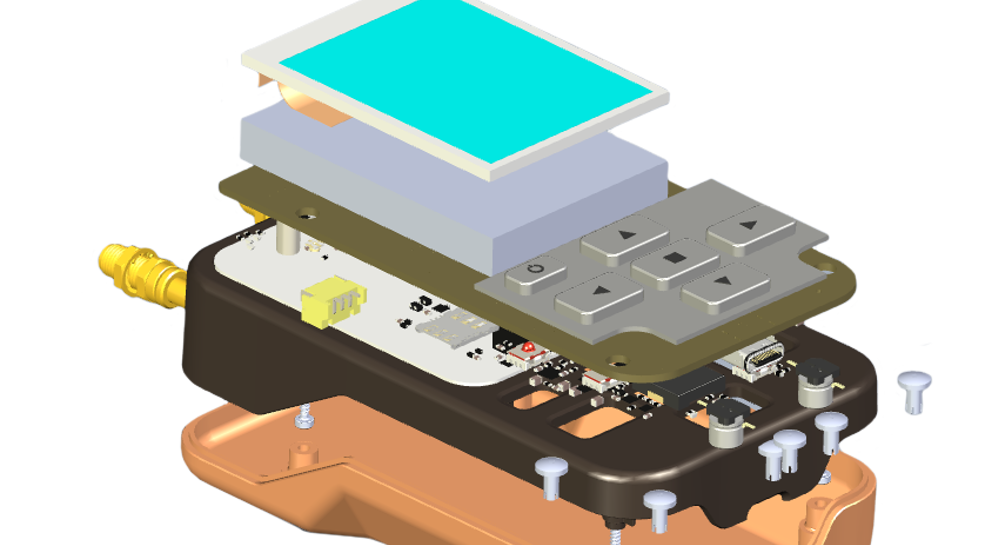

A mechanically and electrically integrated solution combining input and output – typically a keypad with a display. This type of assembly supports efficient signal routing, and is delivered ready for plug-and-play installation in your system.

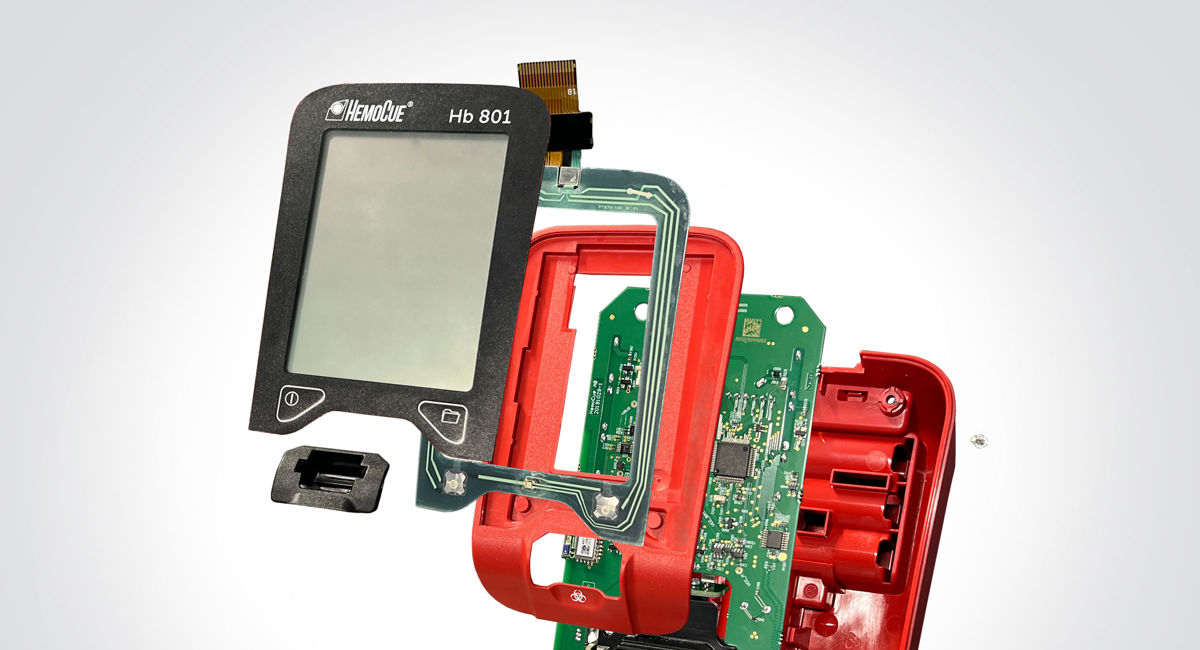

A complete, self-contained input module – ready for direct electrical integration into your product. These assemblies typically include keypad, display, PCBA, wiring and housing – delivered as a tested and documented unit under a single item number.

Co-moulding unites the housing and the interface into one integrated component. By moulding soft-touch silicone directly onto a rigid plastic structure, separate assembly steps are removed while enabling high IP protection, durability and a clean, unified design.

As with multifunction assemblies and HMI modules, co-moulding offers an efficient path to compact, robust HMI units – ideal for wearables and harsh environments where sealing and ergonomics are essential.

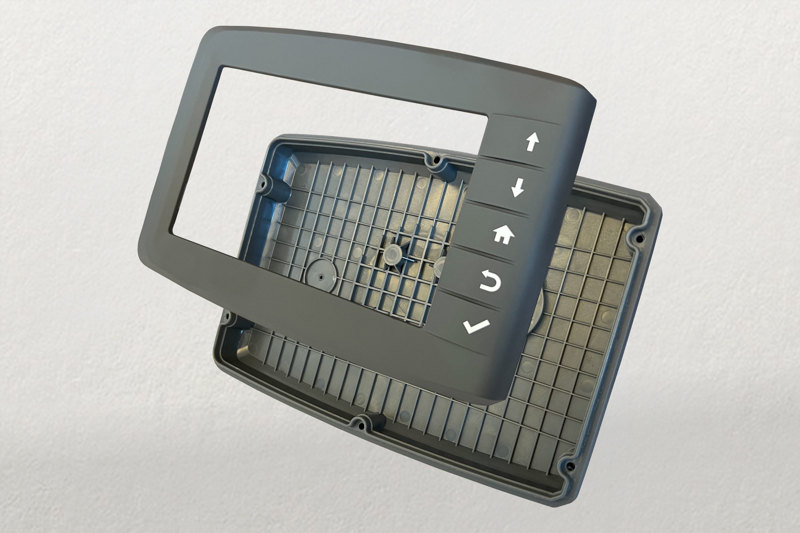

A well-designed enclosure supports the complete HMI assembly and defines how the final product is experienced. We develop customised enclosures that are engineered to fit your electronics, displays, PCBs and connectors – ensuring mechanical precision and straightforward integration with any of the assembly levels described above.

Whether your solution requires bent and formed sheet metal, CNC-milled parts or 3D-printed prototypes, the enclosure becomes a seamless part of the complete HMI solution, helping streamline your supply chain and reduce time-to-market.

-

Download HMI lookbook, offering inspiration, best practice and use casesDownload HMI lookbook

Download HMI lookbook, offering inspiration, best practice and use casesDownload HMI lookbook -

Order a free keypad sample box to make your design process easier and more efficientOrder free keypad sample

Order a free keypad sample box to make your design process easier and more efficientOrder free keypad sample -

Watch short webinars on demand about design and construction of different HMI solutionsWatch HMI webinars

Watch short webinars on demand about design and construction of different HMI solutionsWatch HMI webinars

HMI insights

Get in touch with us

Save R&D time & resources

Focus your R&D efforts where they create the most value – and let us handle the HMI. We manage the entire development process, including component sourcing, material selection, prototyping, testing and logistics. One partner – all in one place.

Simplify

supply chain

With Mekoprint as your HMI partner, you get a streamlined supply chain and full quality assurance. We handle the complete tolerance chain, documentation and testing – so you only deal with one supplier for the entire HMI assembly.

Time-saving assembly

On your production line, you only need to interface with one fully integrated HMI assembly. This reduces assembly time and simplifies both manufacturing and quality control.