Download free lookbook

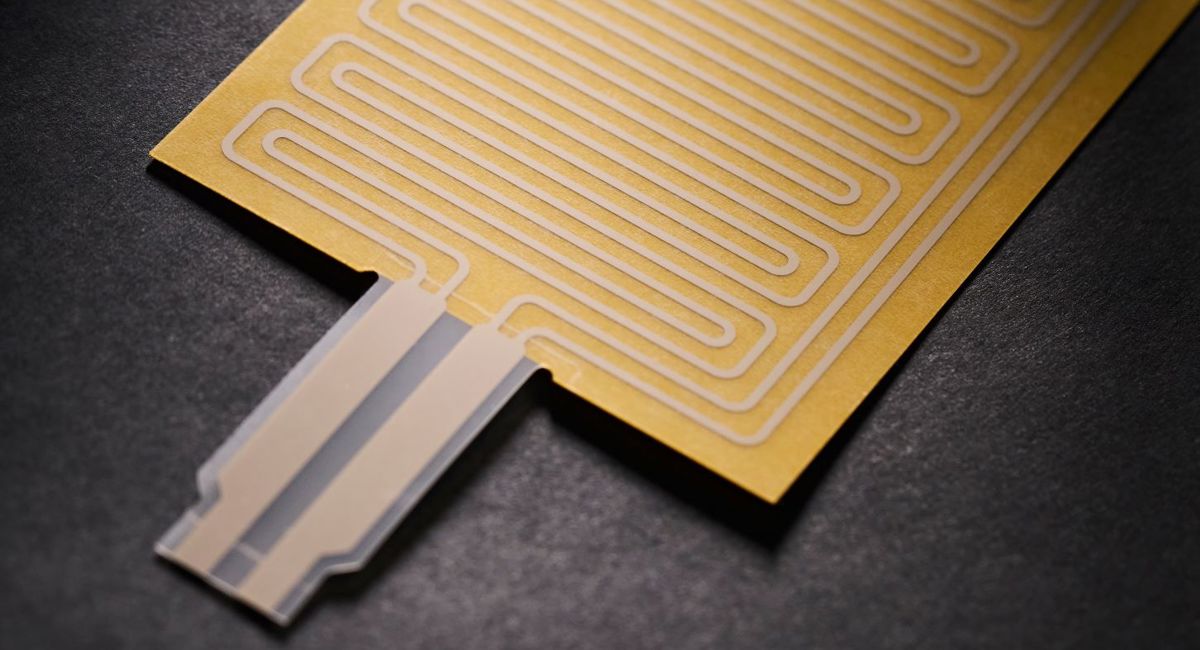

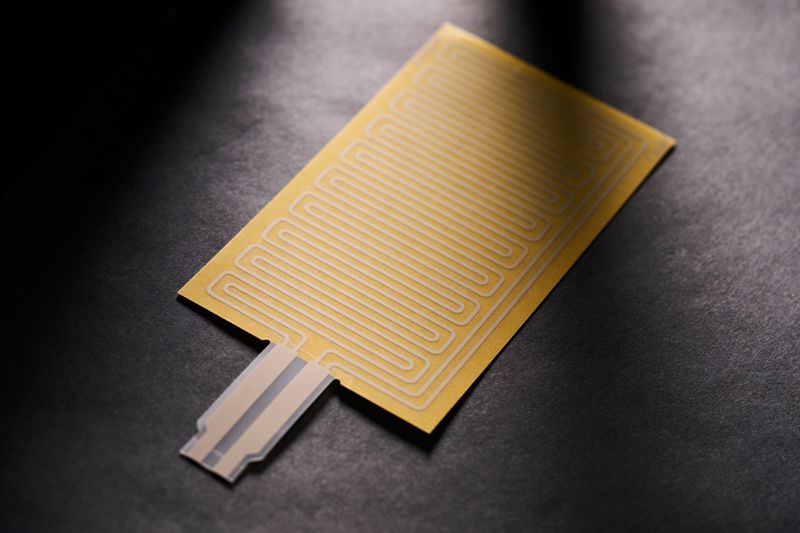

Engineering a printed heater

Printed heaters can be made with either positive temperature coefficient (PTC) ink or conventional carbon or silver ink. Each type offers advantages to meet the heating requirements of the final product.

PTC ink heaters are known for self-regulating properties, which provide a significant safety advantage by preventing overheating. On the other hand, resistive heaters made from conventional carbon or silver are valued for their robustness and versatility in various applications.

Printed heaters made with PTC ink stand out due to their safety features. They increase resistance as the temperature rises, reducing the current flow and thereby avoiding the risk of overheating, and potentially damaging the product.

The self-regulating nature of PTC ink makes the heaters suitable for environments where safety is a paramount concern, e.g. in medical devices or wearable technology.

Additionally, these heaters offer precise temperature control and uniform heat distribution. Together with a more energy-efficient power consumption once the desired temperature is reached.

Heaters made with conventional carbon or silver are highly appreciated for their cost-effectiveness and ease of production.

They can be produced at a lower cost compared to PTC ink heaters, making them an economical option for larger scale applications.

The flexibility in design also allows for integration into various products without significant modifications.

-

Download our lookbook for an insight to technology, building blocks, use cases, industry trends, and more inspiration.Printed electronics lookbook

Download our lookbook for an insight to technology, building blocks, use cases, industry trends, and more inspiration.Printed electronics lookbook -

Watch our short webinars about printed electronicsWatch Printed Electronics webinars

Watch our short webinars about printed electronicsWatch Printed Electronics webinars -

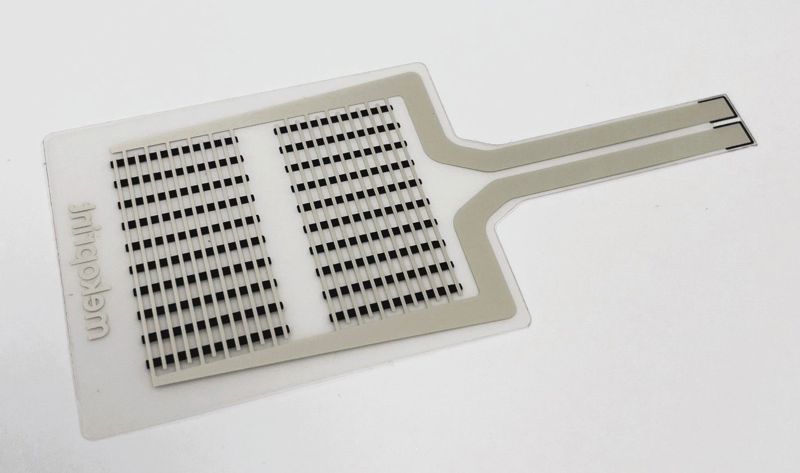

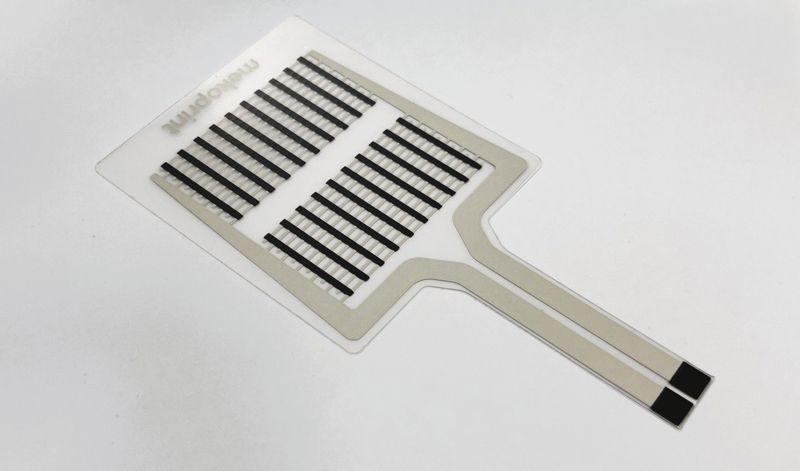

Order a printed electronic sensor sample to make your process easier and more efficientOrder printed sensor sample

Order a printed electronic sensor sample to make your process easier and more efficientOrder printed sensor sample

Get in touch with us

Order free product sample

-

Development, production maturation, and large-scale production in collaboration with our engineering team.Engineering printed electronics

Development, production maturation, and large-scale production in collaboration with our engineering team.Engineering printed electronics -

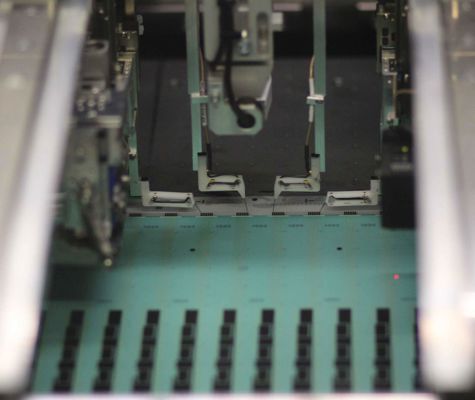

Automated manufacturing of large-scale printed electronic sensors and circuits with uniform design.Production of printed electronics

Automated manufacturing of large-scale printed electronic sensors and circuits with uniform design.Production of printed electronics -

Automated electrical function test of printed electronic components on rolls. Tailored to each individual project.Test of printed electronics

Automated electrical function test of printed electronic components on rolls. Tailored to each individual project.Test of printed electronics