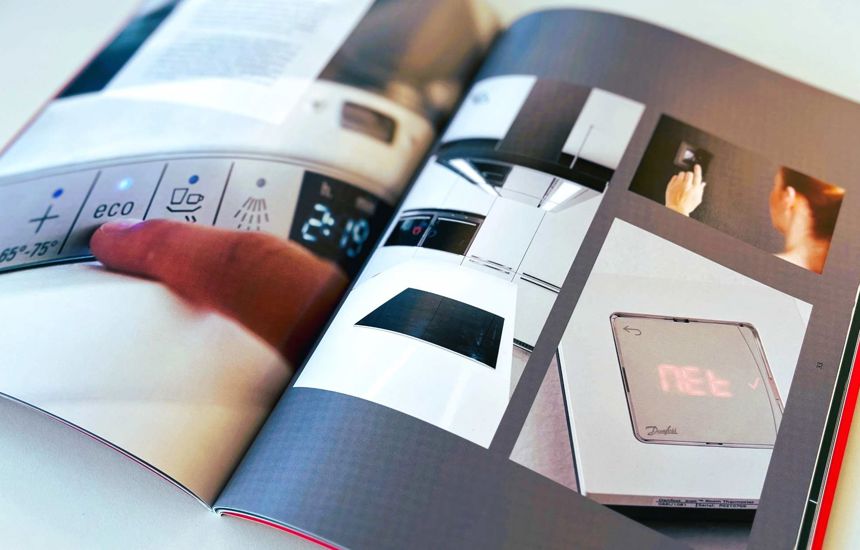

Our long-term customer needed an improved robustness of the capacitive touch sensor used for one of their control panels – We investigated and implemented a technology change.

The task for Mekoprint was to:

The task for Mekoprint was to:

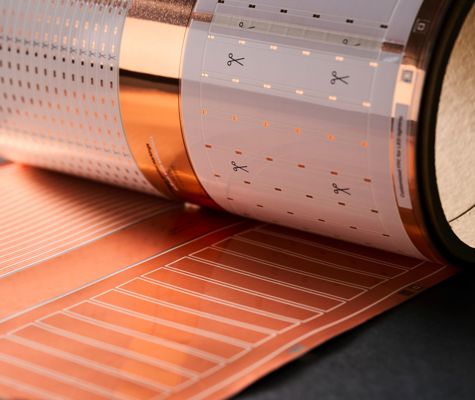

- Qualify roll-to-roll fine line printing of conductive silver traces down to 50 um

- contribute to re-design and lifetime qualification of the capacitive touch sensors

- and subsequently to deliver the technology in mass production

Besides qualification of new production technology, the open dialogue and trust, also created a strong platform for collaborating and achieving higher quality and delivery performance for both parties.

Investments in 100% test of all sensors

In the production of the ultra-thin fine line traces, the human eye falls short.

Hence, investments were made in automated optical inspection systems and flying probe electrical test technology.

This project improved the solution for our customer. But the learning and investments made will benefit all other customers – with production, test and vision systems supporting low ppm-levels.

- State-of-the-art automated optical inspection systems

Implemented in several key processes throughout production

- Roll-to-roll flying probe electrical test technology

Making it possible to test the functionality of all sensors before shipment

Key Account Manager, Printed Electronics

Anders Menholt

Key Account Manager, Printed Electronics

Anders Menholt

Download free lookbook

-

Cost-efficient, lightweight, and flexible user interfaces in applications where touch operation is preferred.Capacitive touch sensors

Cost-efficient, lightweight, and flexible user interfaces in applications where touch operation is preferred.Capacitive touch sensors -

Development, production maturation, and large-scale production in collaboration with our engineering team.Engineering printed electronics

Development, production maturation, and large-scale production in collaboration with our engineering team.Engineering printed electronics -

Flexible circuits cut down on space and weight. Ideal for devices where a rigid circuit board will be impractical.Flexible circuits

Flexible circuits cut down on space and weight. Ideal for devices where a rigid circuit board will be impractical.Flexible circuits