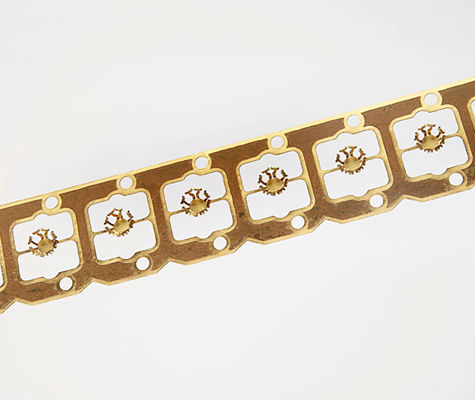

With its expertise in advanced micro-machining technology, Mekoprint has delivered thousands of EMC shields to CERN, the European Organization for Nuclear Research.

The components protect research equipment from electromagnetic interference, ensuring that CERN's measured data remains reliable

Electronic Engineer at CERN

Georges Blanchot

Micro-machined technology

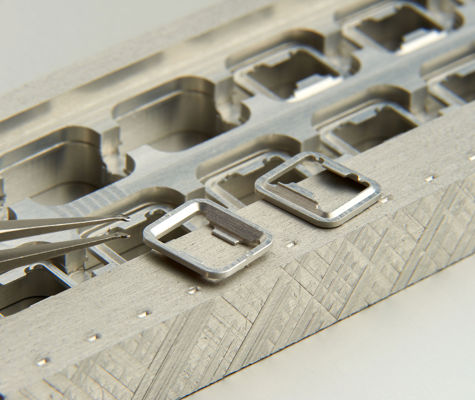

When CERN contacts Mekoprint with design specifications for the small, ultra-thin shields, Mekoprint’s specialists assessed that the design needed to be optimized to meet the desired quality requirements and ensure complete shielding connectivity.

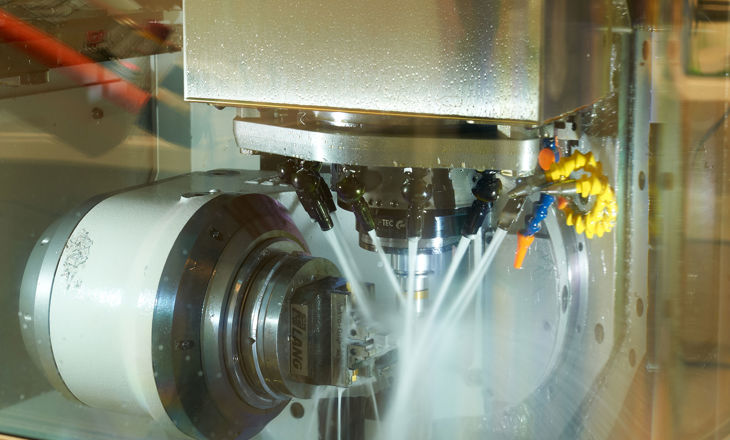

The team proposed using micro-machining to produce the components, meeting the requirements and ensuring a result that could be produced with the necessary precision. This solution proved to be highly beneficial for CERN, as it both optimized the production process and improved the quality of the components.

Shielding ensures precision in particle collisions

CERN operates a complex system of particle accelerators to provide the best conditions for international collaborations in high-energy particle physics. These accelerators are used, among other purposes, to observe and understand the fundamental particles that make up the universe.

To upgrade the measurements in CERN’s largest machine, the Large Hadron Collider, CERN required new EMC shields to be produced.

Electronic Engineer at CERN

Georges Blanchot

Business Manager, Mekoprint Micromechanics

Bjørn Mølbach Krogh

-

Experience precision like never before with our team of skilled experts crafting micro sheet metal parts.Micro sheet metal parts

Experience precision like never before with our team of skilled experts crafting micro sheet metal parts.Micro sheet metal parts -

We offer specialist expertise in micro component solutions and additional resources to ensure your project's progress.Design & engineering of micro solutions

We offer specialist expertise in micro component solutions and additional resources to ensure your project's progress.Design & engineering of micro solutions -

We are specialists in manufacturing micro-milled components for applications where precision and reliability are critical.Micro-milled components

We are specialists in manufacturing micro-milled components for applications where precision and reliability are critical.Micro-milled components