What is CNC Milling?

CNC stands for "Computer Numerical Control." This means that the milling machine is controlled by a computer program, allowing the milling process to be carried out with high precision and speed. This automation reduces the risk of operator errors compared to more manual processes.

CNC control involves loading a file, such as a CAD file, into the program, which provides the computer with exact dimensions of the item to be milled. Information about the material to be used and the tools to be applied is also entered. After this setup, the process operates essentially automatically.

CNC technology is used in most modern milling machines and results in precisely and uniformly shaped items. It enables a highly efficient machining process, even for complex items.

-

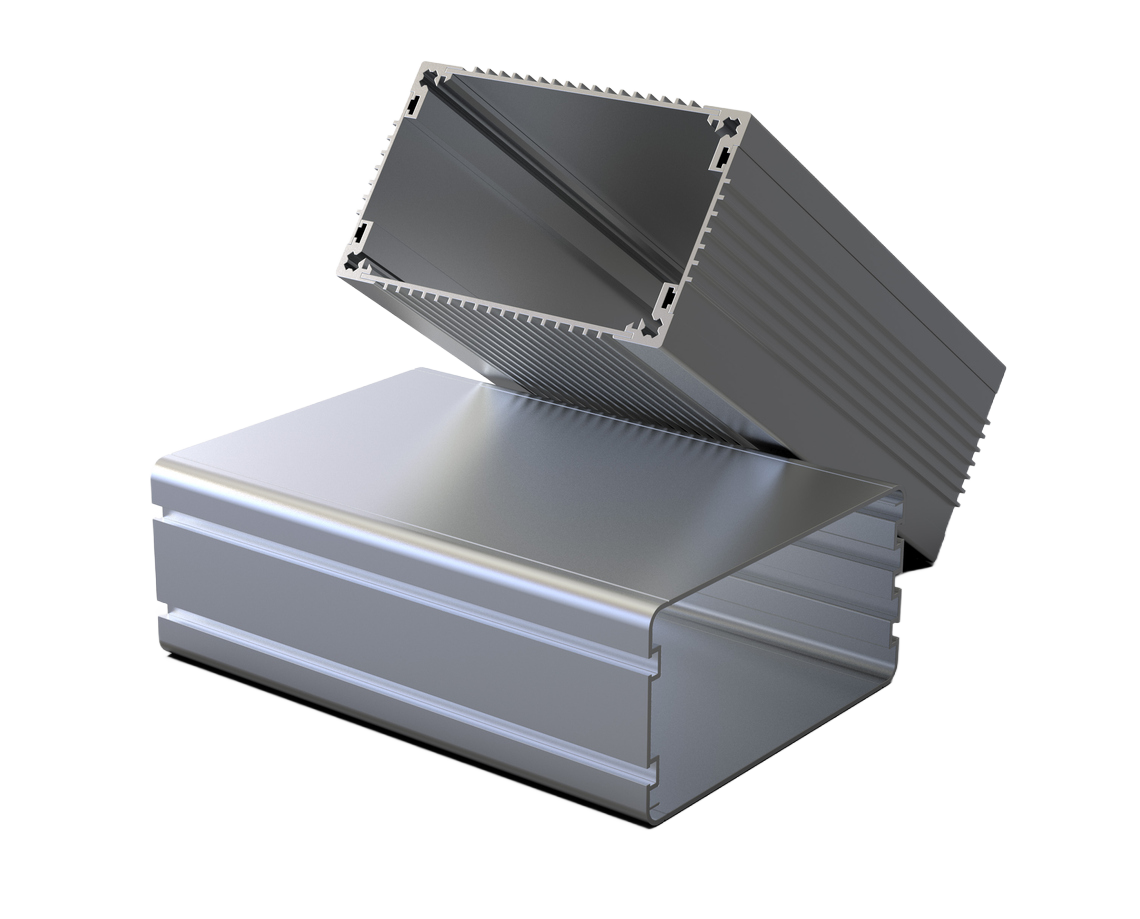

If a product with high strength which can also be adapted completely to customer requirements is desired, chassis parts may be milled from solid blanks.

If a product with high strength which can also be adapted completely to customer requirements is desired, chassis parts may be milled from solid blanks.Assembly details such as threaded bushings can be performed directly as part of the product. Here, the available range of alloys is greater than when using extruded profiles.

-

Mekoprint has extensive experience in the manufacture of cabinets from milled metal parts.

Mekoprint has extensive experience in the manufacture of cabinets from milled metal parts.Mekoprint has a wide range of machinery, which allows the company to choose the machine that is the fastest and offers the highest capability to ensure that workpieces are the right price, without compromising on quality.

-

Mekoprint has years of experience in the manufacture of precision workpieces, ensuring that workpieces are designed optimally for their use. We are very focused on dimensions and tolerances which, like the agreed delivery time, we meet.

Mekoprint has years of experience in the manufacture of precision workpieces, ensuring that workpieces are designed optimally for their use. We are very focused on dimensions and tolerances which, like the agreed delivery time, we meet.Milling workpieces in solid materials on machines with a high capability allows for a high degree of accuracy and precision. Details can be mutually processed with tolerance zones of a few hundredths of a millimetre. The use of special tools can provide a process with a high degree of accuracy and a shorter process time. By choosing alloys which are suitable for both the product and process, it is possible to achieve a high degree of certainty in the process and precision of the machining.

-

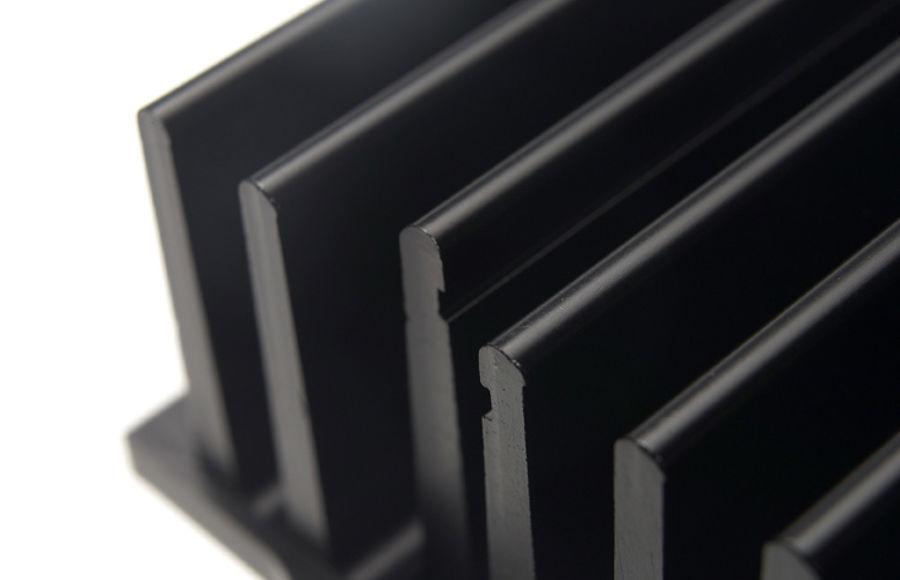

Mekoprint has many years of experience in producing heat sinks from milled metal workpieces. We have a wide range of machinery, which enables us to choose the machine that ensures that the workpieces are produced the fastest, of the right quality and at the right price.

Mekoprint has many years of experience in producing heat sinks from milled metal workpieces. We have a wide range of machinery, which enables us to choose the machine that ensures that the workpieces are produced the fastest, of the right quality and at the right price.We manufacture our clamping fixtures ourselves, predominantly based on vacuum, which means saving time and money.

Key Account Manager, Mekoprint

Preben Bo Sørensen

Customer stories

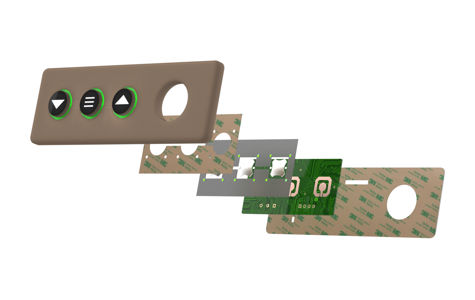

Milled metal parts often go through a process where the following technologies, which Mekoprint has gathered under their own roof, are used:

Milled metal parts often go through a process where the following technologies, which Mekoprint has gathered under their own roof, are used: