Explore the evolving possibilities of printed electronics

Our focal point is to make printed electronics components that fit your final application perfectly. At Mekoprint we develop and manufacture customised printed sensors and circuits for a wide variety of industries. We have been doing this for decades.

The opportunities in printed electronics have grown a lot in recent years, and together we are continually pushing the boundaries even further.

-

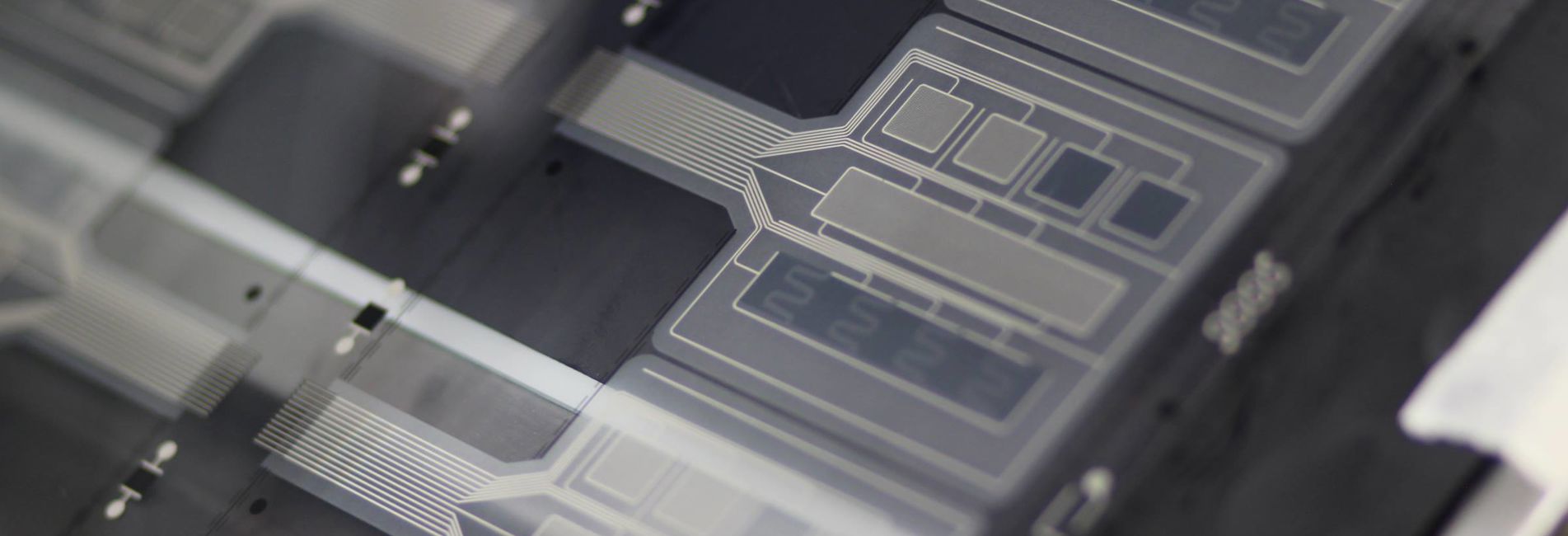

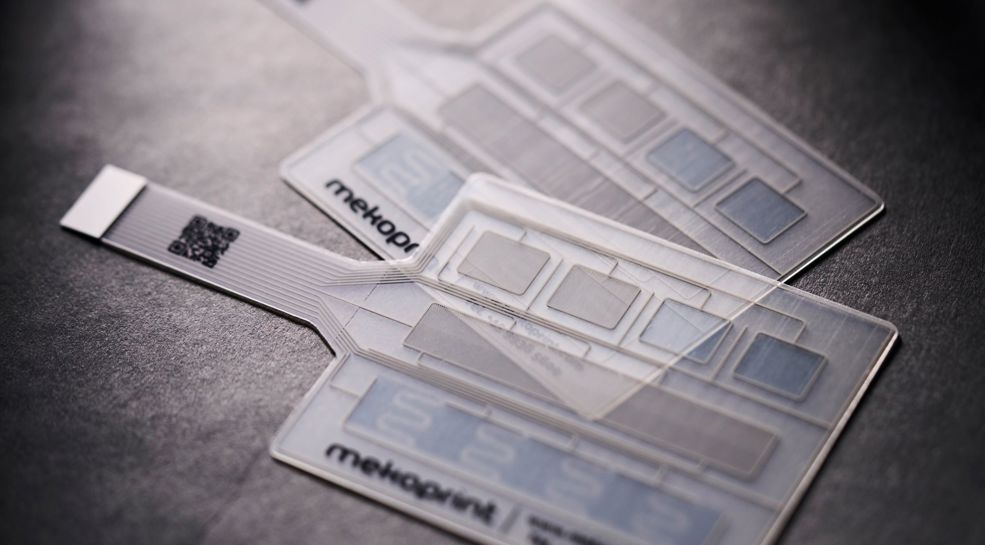

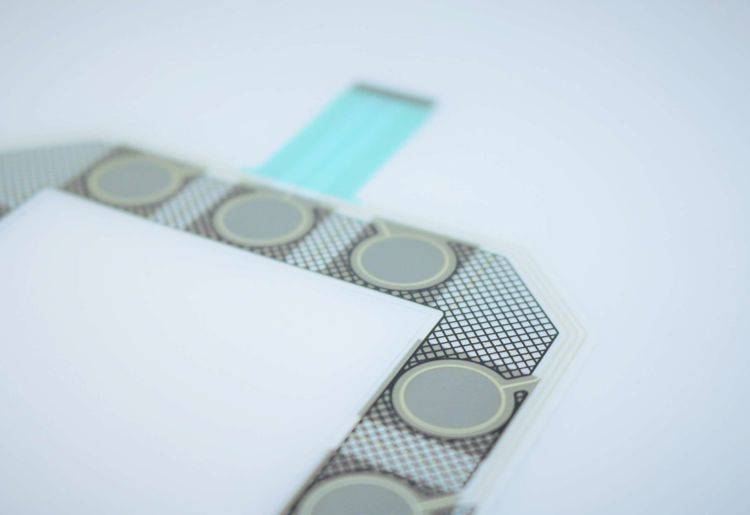

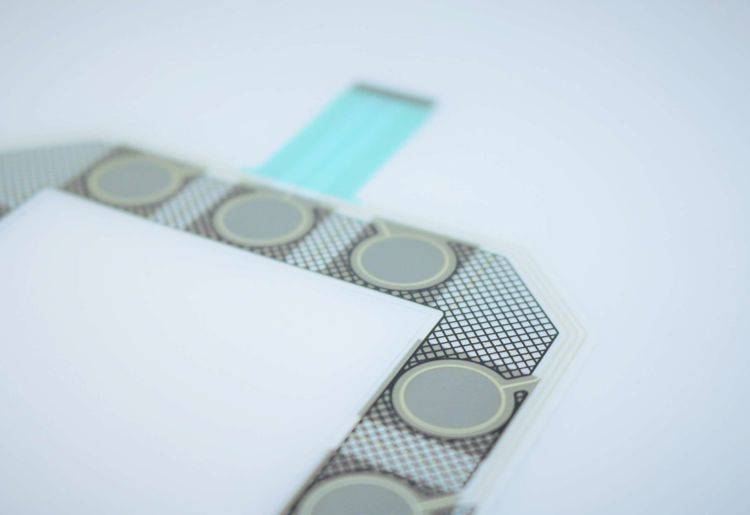

Capacitive touch sensors printed on thin polymer films are often used as cost efficient, lightweight as HMI solution. Especially in applications where touch operation is the preferred way to interact.

-

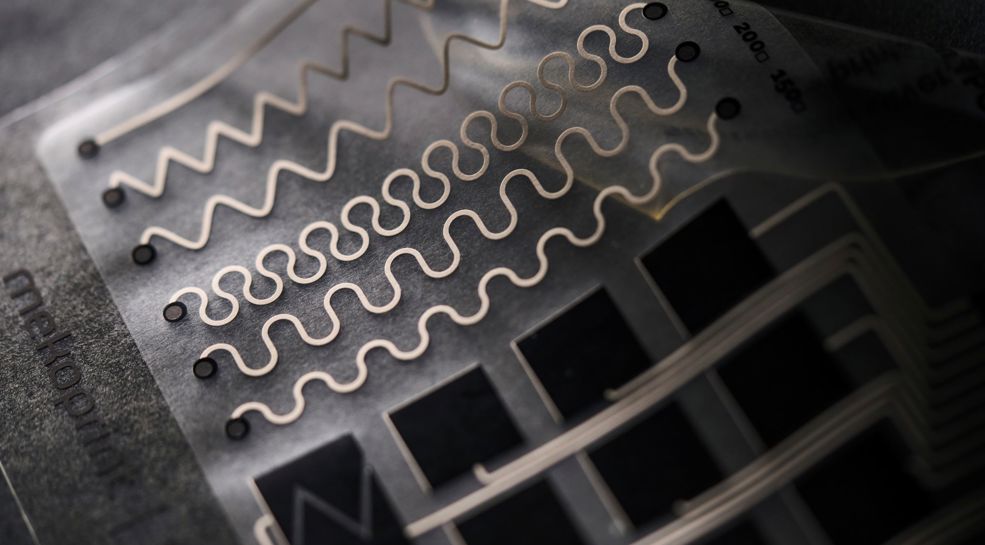

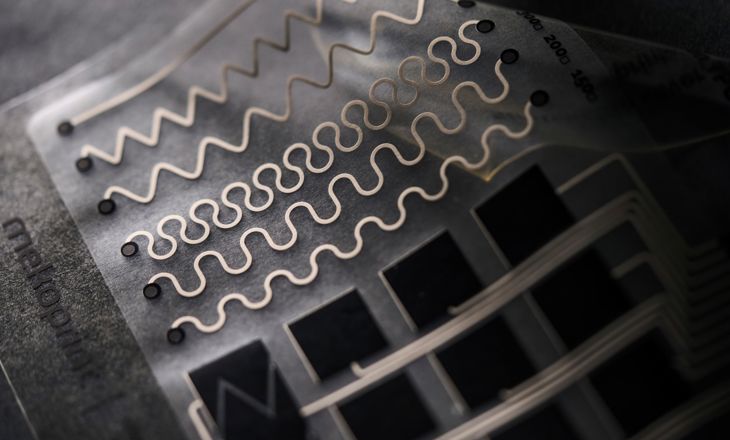

Wearable printed sensors are an important part of the disposable healthcare market. They are made on ultra-thin bendable or stretchable materials. Ideal for placing directly on the skin or wearing close to the body.

-

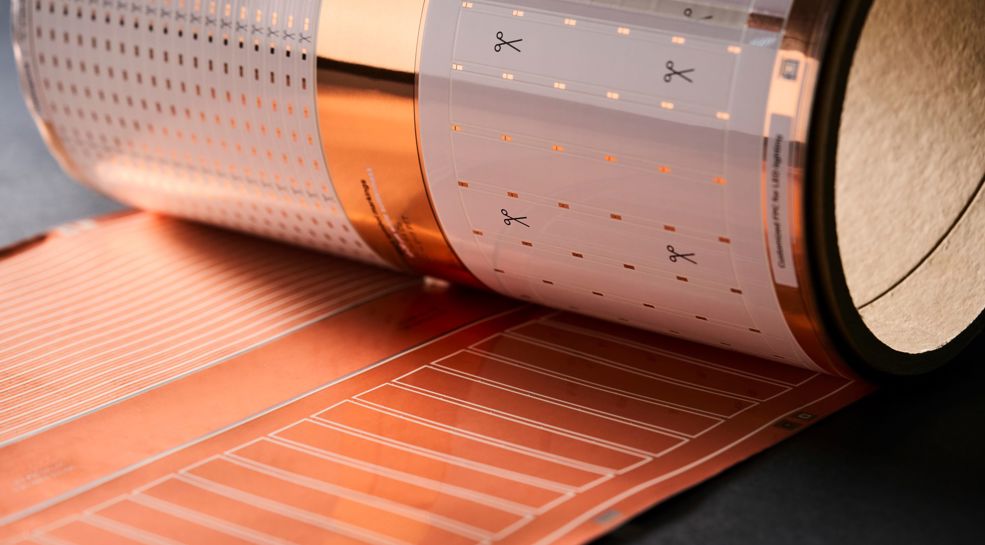

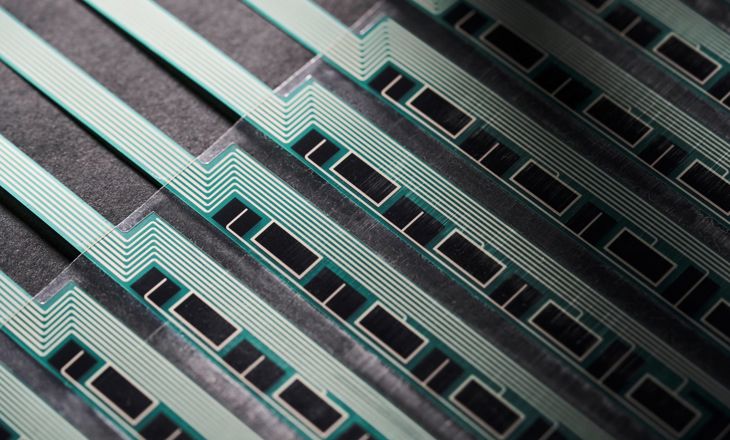

Flexible printed circuits made from copper laminated polymer foils are especially good for carrying electricity. They support electronic devices requiring high flexibility, or where a rigid circuit board would be impractical.

-

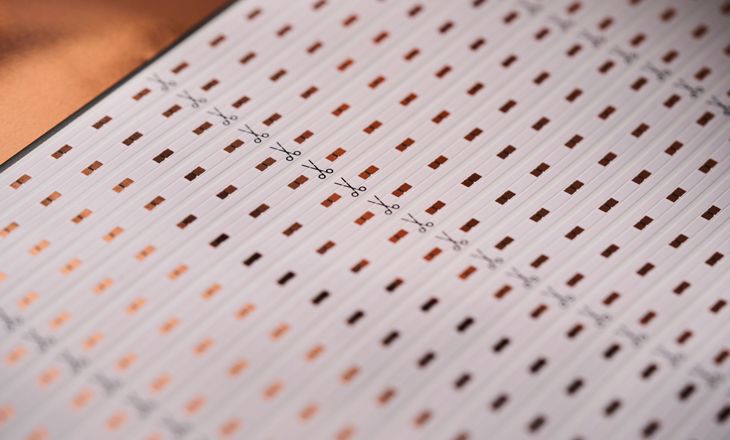

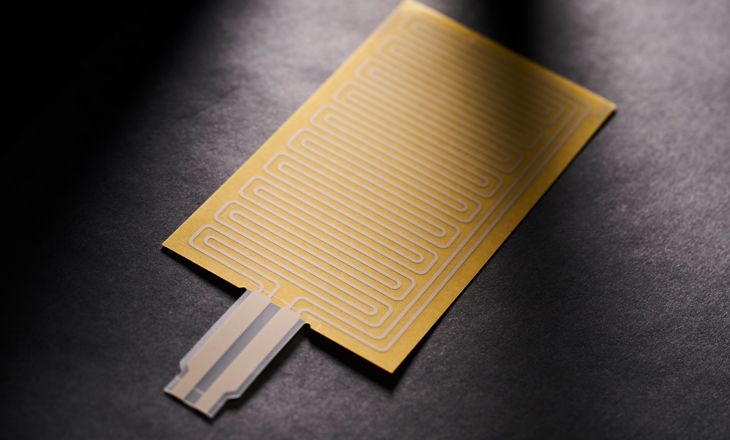

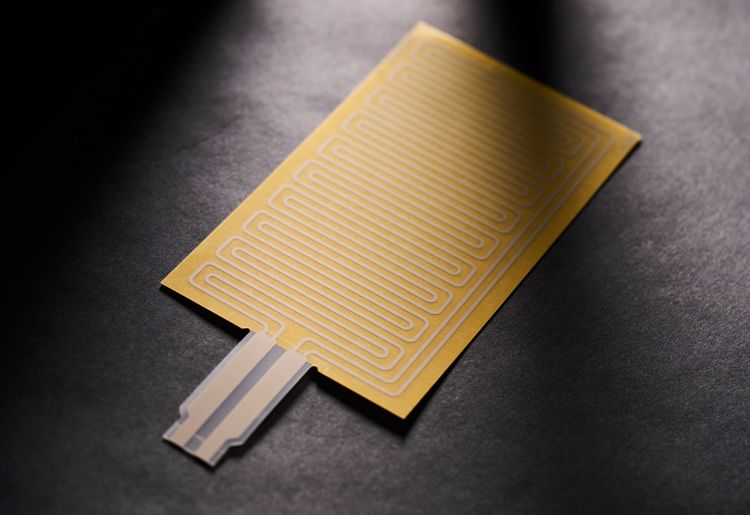

Printed heaters are made of lightweight and flexible polymer foil. Easy to fit into applications without any big changes to design.

Typically used in construction, building design, and various other applications where thin heating elements are useful.

-

Specialised in printed electronics, our engineers are your go-to for everything within product development, production maturation, and high volume production.

Building blocks of printed electronics

-

The core of all printed electronics begins with the right choice of conductive inks. The choice is based on the needed level of functionality, quality, and price.

At Mekoprint you can benefit from a number of already tested and proven inks. Or we will assist in finding new and adapted inks to fit your specific application.

-

When using printed electronics as a key component in your application, it is important to consider properties of the substrates.

You will have to choose from a number of features, as different materials support components thickness, light diffusion, weight, bendability, stretchability, and more.

-

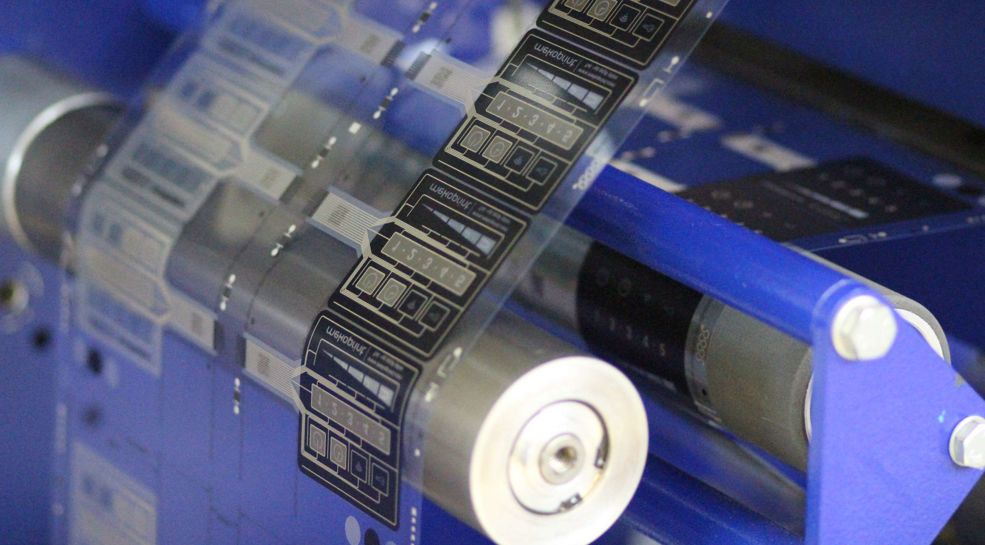

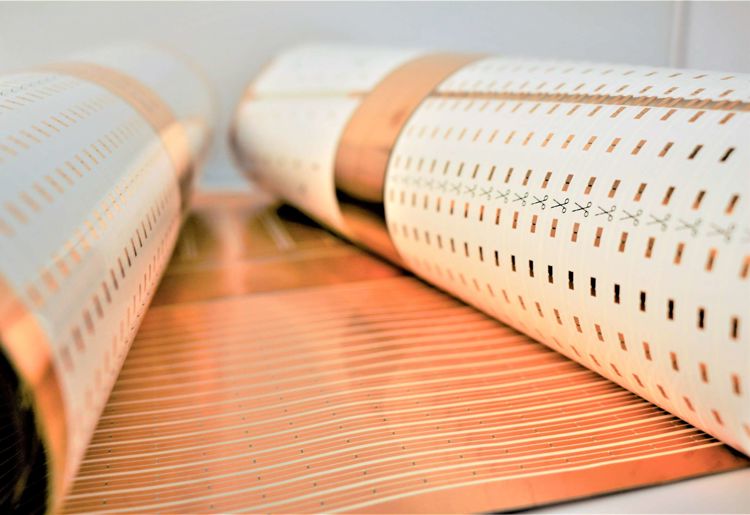

Roll-to-roll screen printing is perfect for mass production of printed electronics. The technology allows high automation enabling lower costs and high uniform quality. As well as the ability to make complex structures with exact precision.

Together we will choose the right manufacturing method to suit your project.

-

Printed electronics are pushing the limits for electrical components by being smaller, thinner, and even transparent at a level where the human eye cannot detect errors.

At Mekoprint we have developed electrical test systems and automated optical inspection to ensure that only functional components are shipped to your factory.

Download free lookbook