Stretchable and flexible materials

-

PET-foils are lightweight substrates offering good flexibility ideal for curved surfaces, flexible electronics, and wearable sensors.

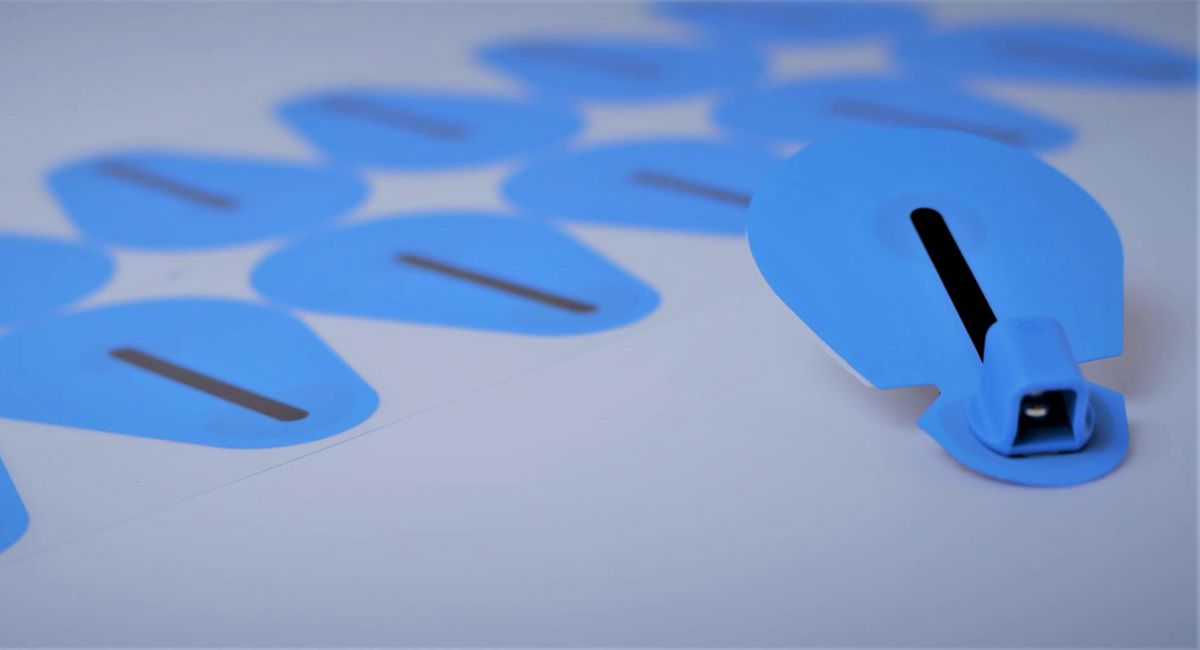

While PET lacks inherent stretchable properties, it remains a popular choice as a substrate for wearable sensors.

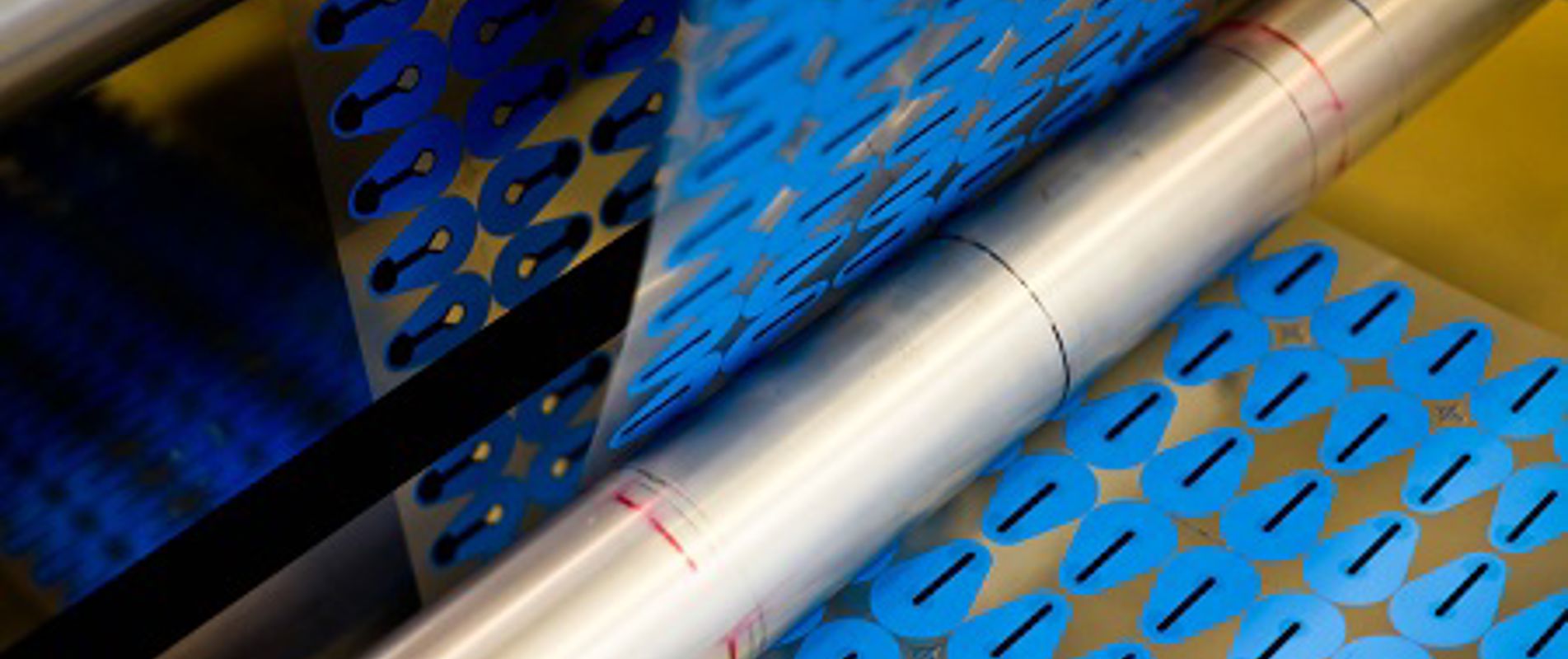

Through sensor design, stretchability can be achieved by cutting e.g. rib or honeycomb structures, allowing the material to stretch without compromising functionality. One notable advantage of this approach is that neither substrate nor ink undergoes stretching. Instead, they are merely bend to fit the body closely.

-

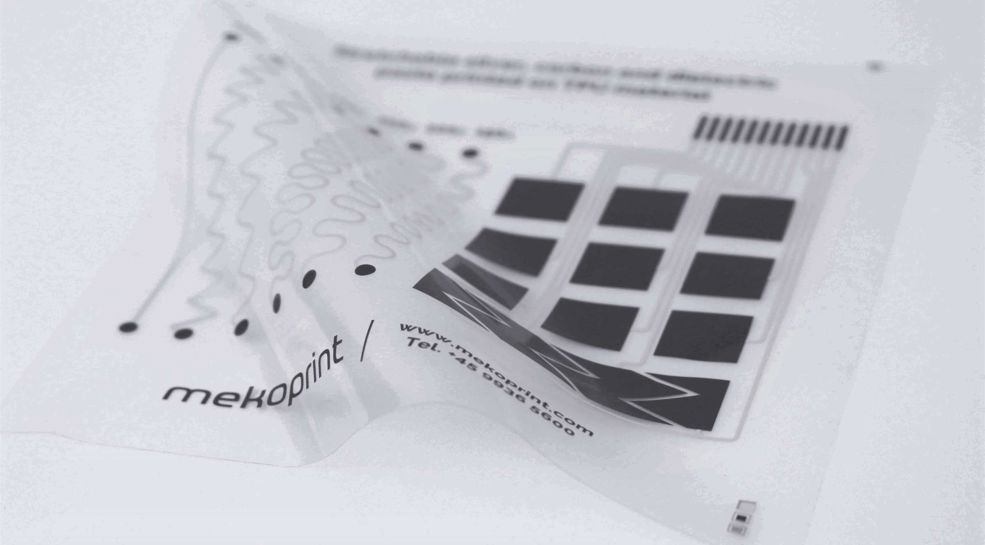

This fabric-like material is thinner than paper looking like a piece of textile. It's made of closely laid fibres on a breathable plastic-coated foil.

Non-woven materials provide an ideal substrate for stretchable sensors using pastes of silver, graphite, graphic colours, and lacquers. The sensors may stretch a little (up to 10%).

Using the latest roll-to-roll screen printing equipment, we make sure your sensors come out perfect, without any folds, cracks, or stretch issues during ink drying.

-

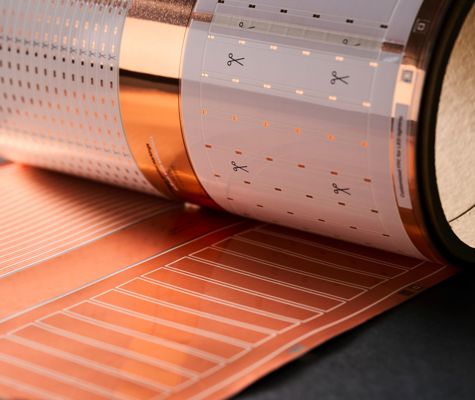

TPU-foils is known for being ultra-thin, transparent, and remarkably stretchable (up to 100%), It sets new standards in stretchable electronics, empowering innovation across industries.

This foil serves as substrate for creating conductive circuits of unparalleled flexibility. With stretchable silver, graphite, graphic colours, and lacquers, the possibilities are endless.

The TPU foil is mounted on a silicone-coated liner. This offers heat stability and seamless handling throughout the manufacturing process.

Download free lookbook

Order free product sample

-

Cost-efficient, lightweight, and flexible user interfaces in applications where touch operation is preferred.Capacitive touch sensors

Cost-efficient, lightweight, and flexible user interfaces in applications where touch operation is preferred.Capacitive touch sensors -

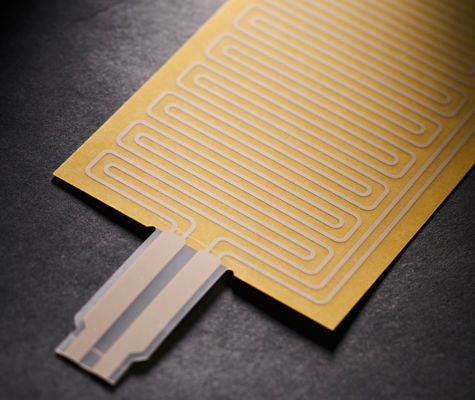

Lightweight and thin printed heaters. Flexible structure, easy to integrate and tailored to any shape and size.Printed heaters

Lightweight and thin printed heaters. Flexible structure, easy to integrate and tailored to any shape and size.Printed heaters -

Flexible circuits cut down on space and weight. Ideal for devices where a rigid circuit board will be impractical.Flexible circuits

Flexible circuits cut down on space and weight. Ideal for devices where a rigid circuit board will be impractical.Flexible circuits

-

Development, production maturation, and large-scale production in collaboration with our engineering team.Engineering printed electronics

Development, production maturation, and large-scale production in collaboration with our engineering team.Engineering printed electronics -

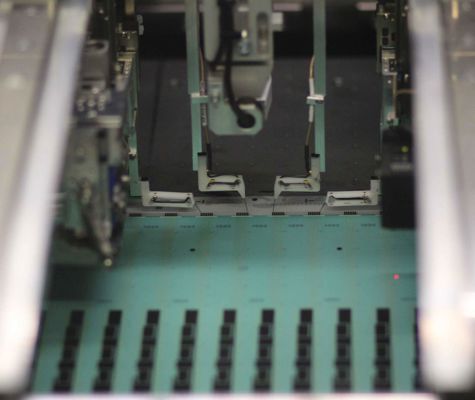

Automated manufacturing of large-scale printed electronic sensors and circuits with uniform design.Production of printed electronics

Automated manufacturing of large-scale printed electronic sensors and circuits with uniform design.Production of printed electronics -

Automated electrical function test of printed electronic components on rolls. Tailored to each individual project.Test of printed electronics

Automated electrical function test of printed electronic components on rolls. Tailored to each individual project.Test of printed electronics