Exceptional accurancy & precision

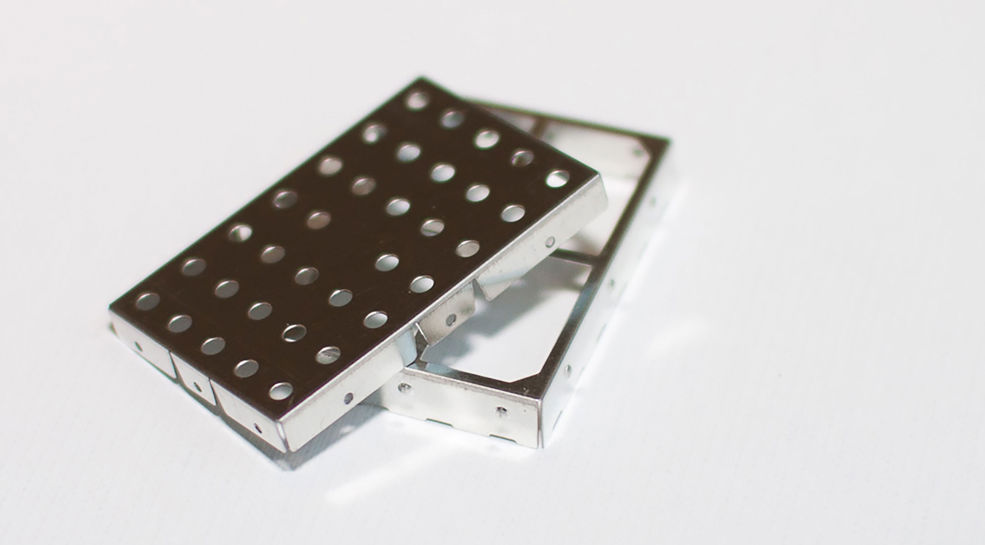

Depending on the requirements, a closed EMI shielding can be manufactured in various ways. It can be milled, where precision and accuracy are emphasized, or spot welded, enabling complex constructions with internal walls. For complete sealing, the shielding can be closed using laser welding, elegantly melting the corners together.

Depending on the requirements, a closed EMI shielding can be manufactured in various ways. It can be milled, where precision and accuracy are emphasized, or spot welded, enabling complex constructions with internal walls. For complete sealing, the shielding can be closed using laser welding, elegantly melting the corners together.

Order a free EMI/RFI sample

Versatile solutions for closed EMI shielding

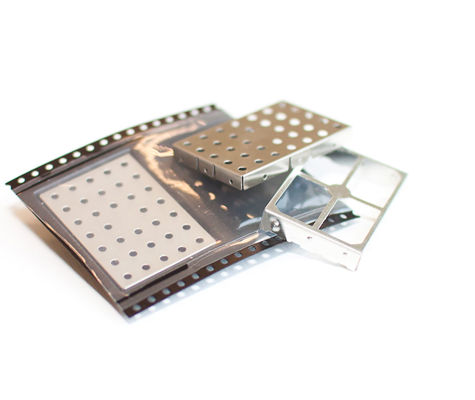

Depending on the requirements, a closed EMI shielding can be manufactured in various ways. It can be milled, where precision and accuracy are emphasized, or spot welded, enabling complex constructions with internal walls. Another option is a frame/lid solution, where the lid securely closes around the frame, creating a solid shield. For complete sealing, the shielding can be closed using laser welding, elegantly melting the corners together.

Depending on the requirements, a closed EMI shielding can be manufactured in various ways. It can be milled, where precision and accuracy are emphasized, or spot welded, enabling complex constructions with internal walls. Another option is a frame/lid solution, where the lid securely closes around the frame, creating a solid shield. For complete sealing, the shielding can be closed using laser welding, elegantly melting the corners together.

-

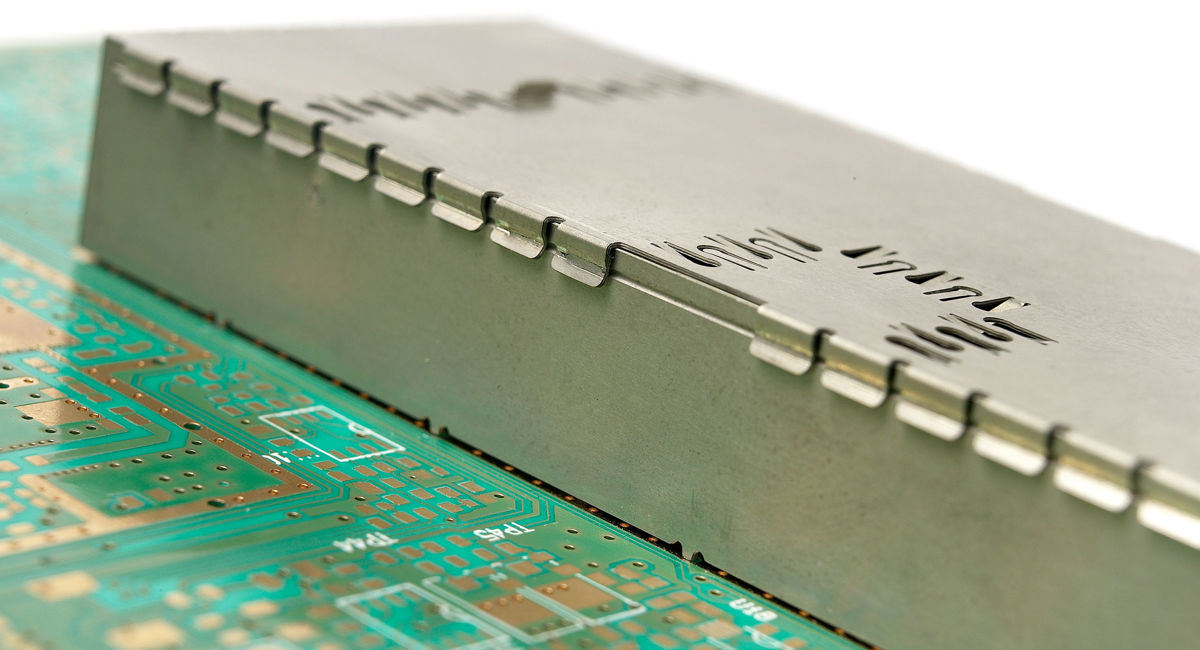

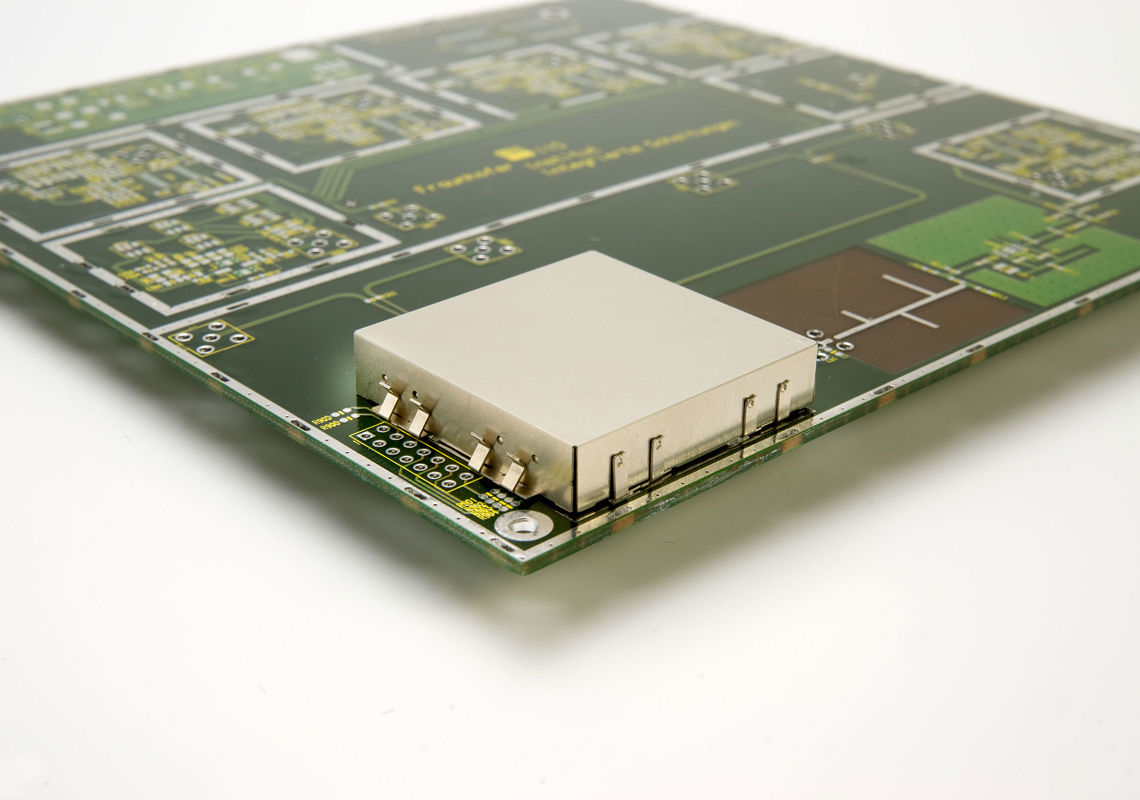

Closed EMI shielding, produced through CNC milling, boasts remarkable precision and accuracy, crucial for effective shielding. This method enables complex designs tailored to electronic components, with wall thicknesses as low as 0.2 mm for optimal customization. With CNC milling, you'll receive a tailored EMI shielding solution that offers precise fitting and superior protection for your electronic components.

-

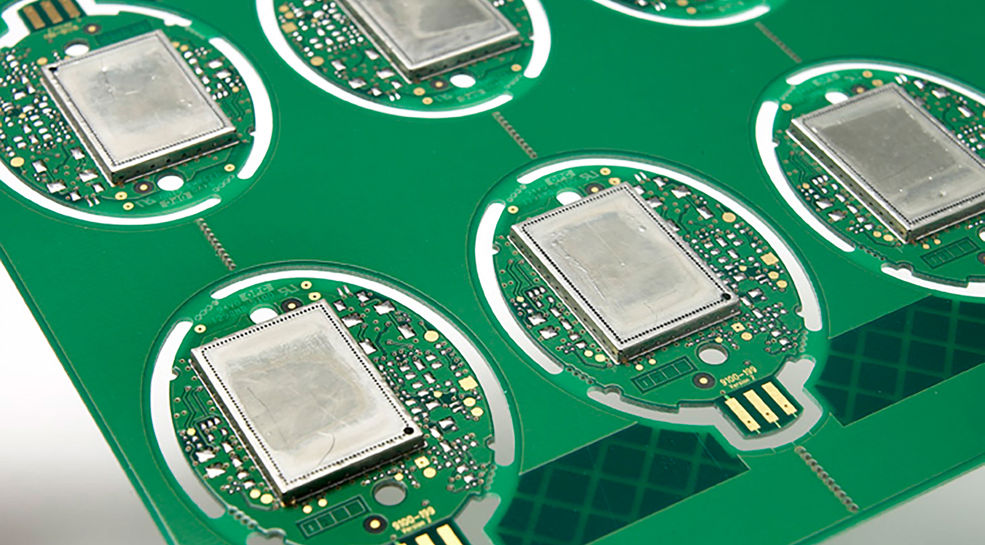

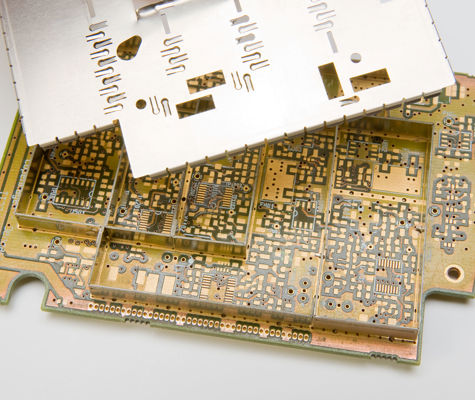

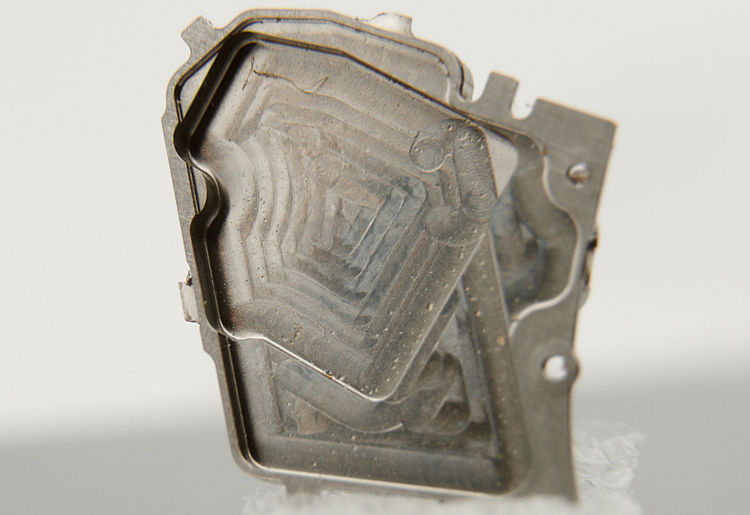

Prior to the welding process, the components undergo etching and bending to ensure precision. With spot welding, internal walls are seamlessly joined, enabling the efficient shielding of multiple components under a single lid.

-

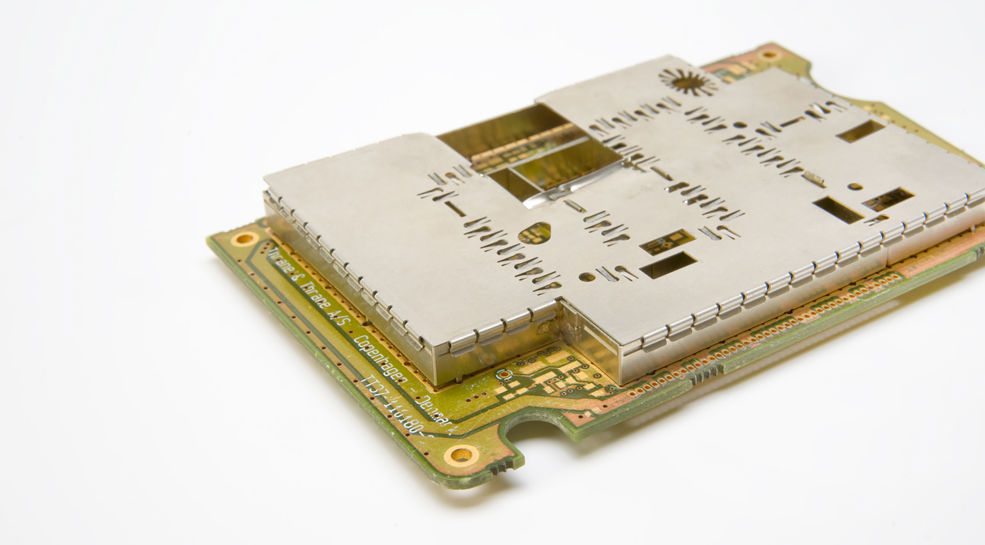

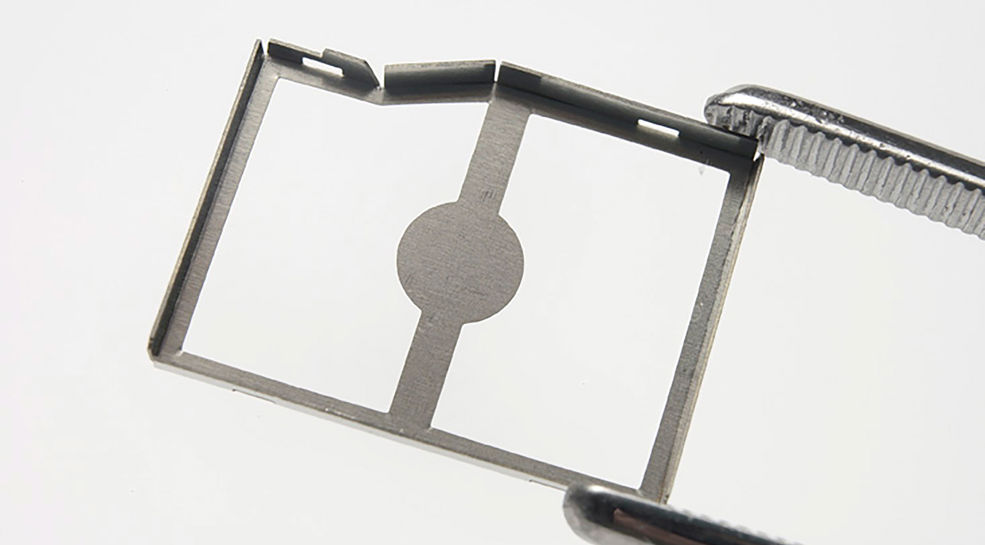

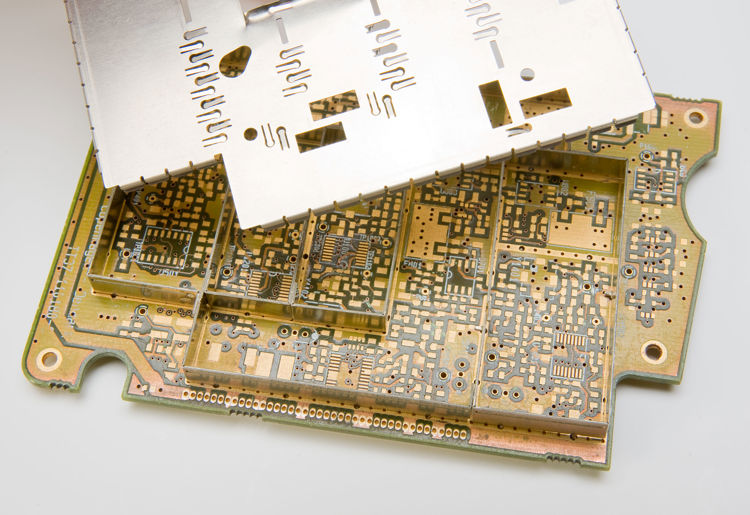

Another option is a frame/lid solution, where the lid securely closes around the frame.

One of the advantages of this approach is its ease of assembly and disassembly. Once the EMI shielding is mounted, you can easily access the PCB board by removing or opening the lid. This is particularly useful for retrofitting or when adjustments or changes need to be made to the components. This flexible assembly and disassembly feature also simplifies the maintenance and repair of the components.

One of the advantages of this approach is its ease of assembly and disassembly. Once the EMI shielding is mounted, you can easily access the PCB board by removing or opening the lid. This is particularly useful for retrofitting or when adjustments or changes need to be made to the components. This flexible assembly and disassembly feature also simplifies the maintenance and repair of the components.