Elevate your EMI/EMC solutions with precision craftsmanship

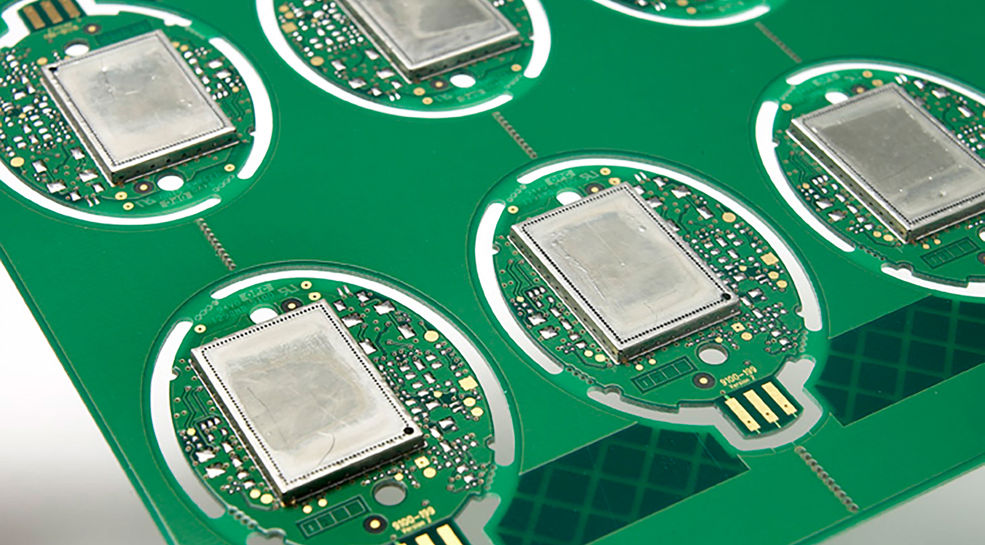

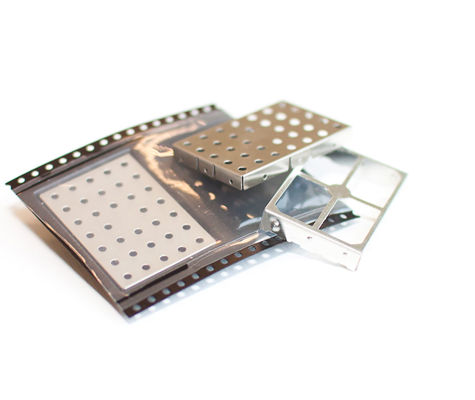

With our versatile production capabilities, we can manufacture customized EMI/EMC shielding solutions ranging from simple designs to the most complex geometries. This flexibility allows us to accommodate various form factors, sizes, and material preferences, ensuring a perfect fit for your application.

We take great pride in our attention to detail, offering customization options such as bending lines, part numbers, and company logos at no additional cost. For optimal performance and durability, we utilize premium materials such as nickel silver, templated steel, stainless steel and other materials carefully selected to withstand even the most demanding environments.

Order a free EMI/RFI sample

Here's what you can expect when you choose our tailored solutions

-

We work closely with you to design the optimal shielding solution, ensuring it perfectly aligns with your requirements and specifications.

-

Whether you need a small batch or large-scale production, we have the capabilities to accommodate your needs, ensuring timely delivery of your customized solution.

-

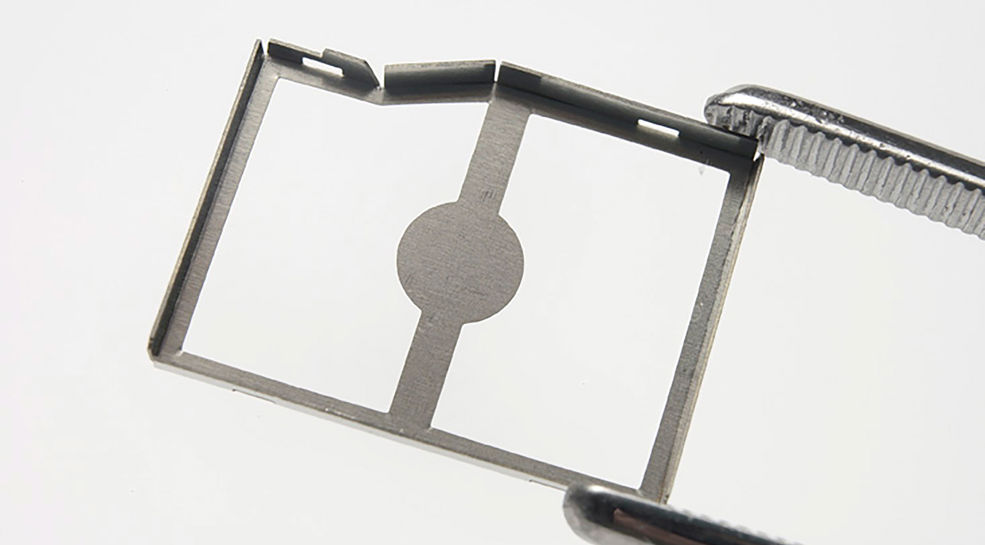

Our etching technology ensures that every component is burr-free and stress-free, guaranteeing superior quality and reliability.

-

From simple designs to complex geometries, we handle every aspect of the production process, ensuring that your shielding solution meets your exact specifications, no matter how complex.

-

We provide custom 3D printed trays designed to seamlessly integrate into your assembly lines. These trays can be made from ESD approved materials and are recyclable, promoting sustainability throughout the product lifecycle.

Precision Processes

We have the capability to both laser cut and etch components before subsequently bending them either by hand or using tools. If the volume is large, we also have the option to stamp components directly from coil material.

We have the capability to both laser cut and etch components before subsequently bending them either by hand or using tools. If the volume is large, we also have the option to stamp components directly from coil material.

-

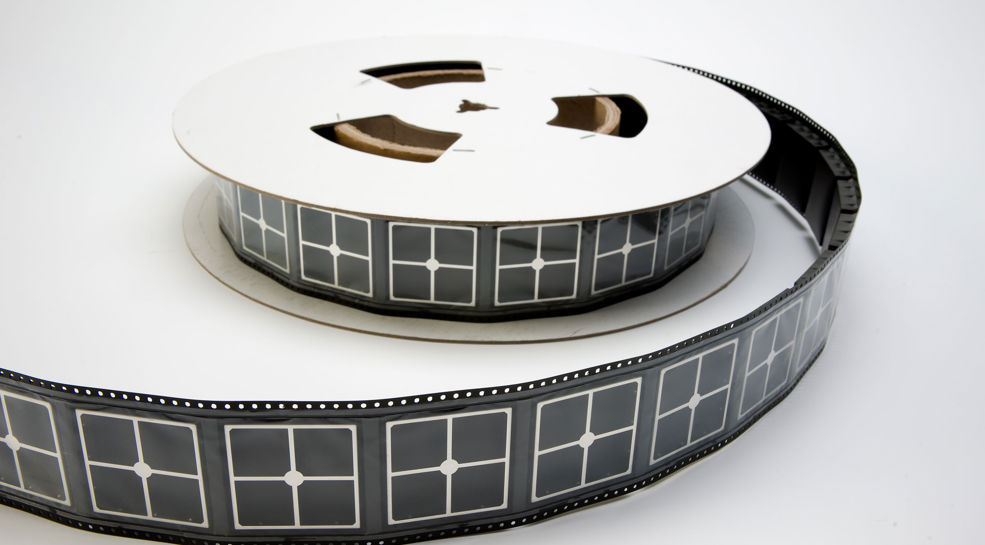

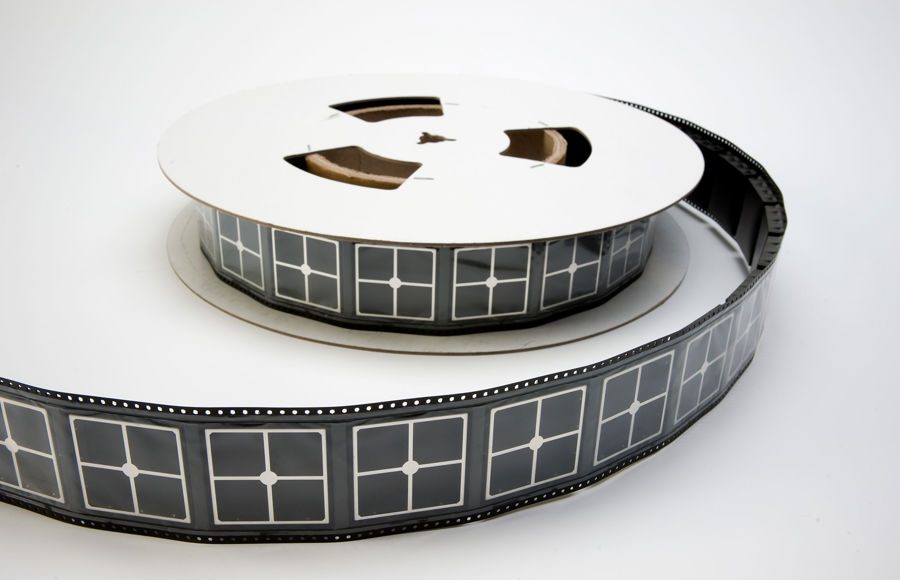

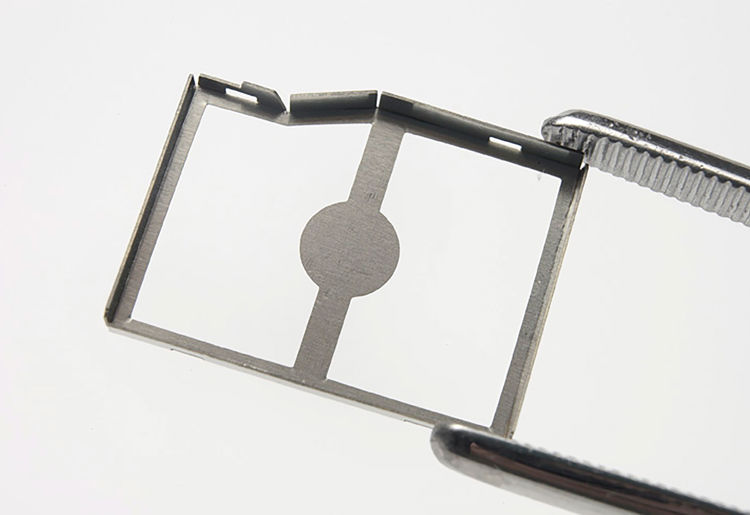

In partnership with our customers, we've pioneered innovative solutions for photo chemical etching. This technology enables the creation of complex shapes and tolerances that traditional methods cannot match. Cost-effective and versatile, it's ideal for materials up to 1.0 mm thick, including stainless steel, copper, brass, and aluminium.

Complex shapes are effortlessly produced across a range of materials, ensuring burrs-free components without any tool costs. We offer fast and flexible delivery with options available in sheets, strips, or rolls to suit your needs.

-

Metal laser cutting allows us to precisely cut both thin plate and fine mechanical components, catering to materials with thicknesses ranging from 0.05mm to 1,5mm. Whether you're working on small or large series sizes, even the most complex geometries are effortlessly handled.

Unlike traditional CNC punching methods, our laser cutting offers faster setup times accommodates a wider range of material thicknesses, and eliminates the need for costly tools. With the ability to work with materials like aluminium, iron, coated iron, stainless steel, and copper, we ensure swift and flexible manufacturing solutions tailored to your exact specifications.

-

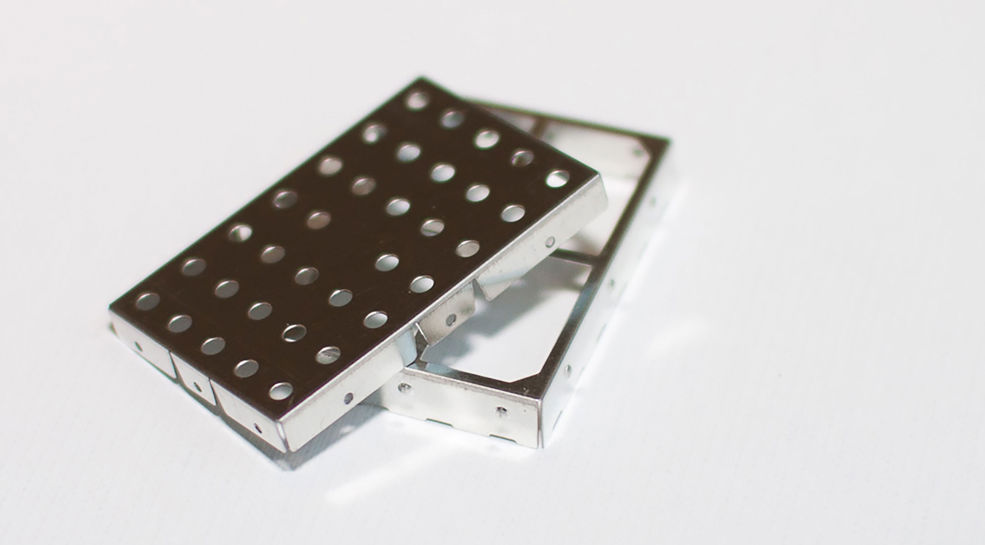

Metal stamping offers a compelling alternative to laser cutting, particularly suitable for medium to large batch sizes, delivering high precision and efficiency. We often employ combined solutions, incorporating bending to achieve the desired shapes effectively. Our automated punching process utilizes specialized punching dies to create complex workpieces featuring holes, embossing, countersinks, or threads.

Whether through progressive die or manual processes, metal stamping offers advantages for both lower and higher volume production, ensuring competitive rates and low unit costs.

-

Achieving the desired shape for EMI shielding often involves one or more bends. That's why we rely on advanced machinery like the Trumpf Trubend 7036 machines. These machines guarantee fast, accurate, and effective results for both small and medium-sized workpieces.

Our dedicated team bends parts according to various specifications, including material thickness ranging from 0.1 mm to 2 mm.

-

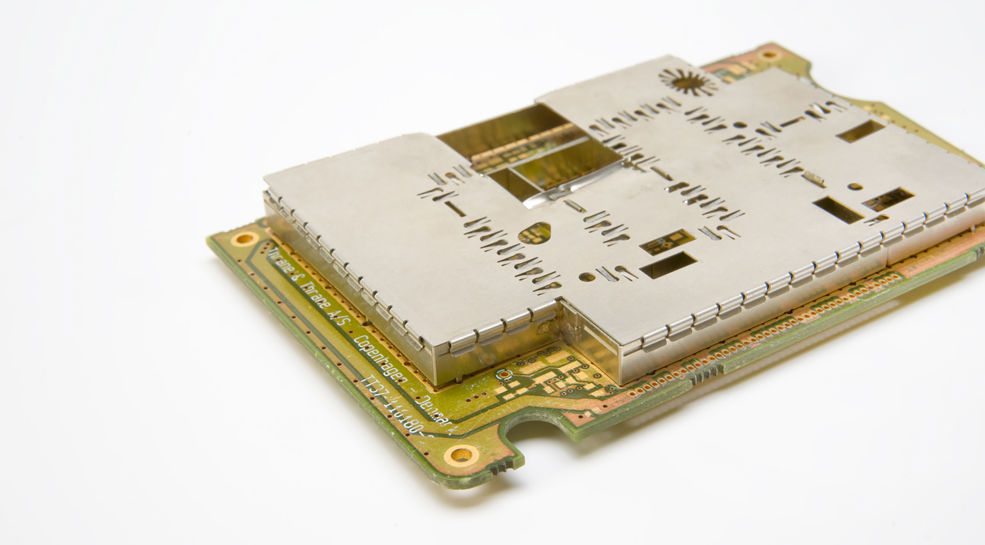

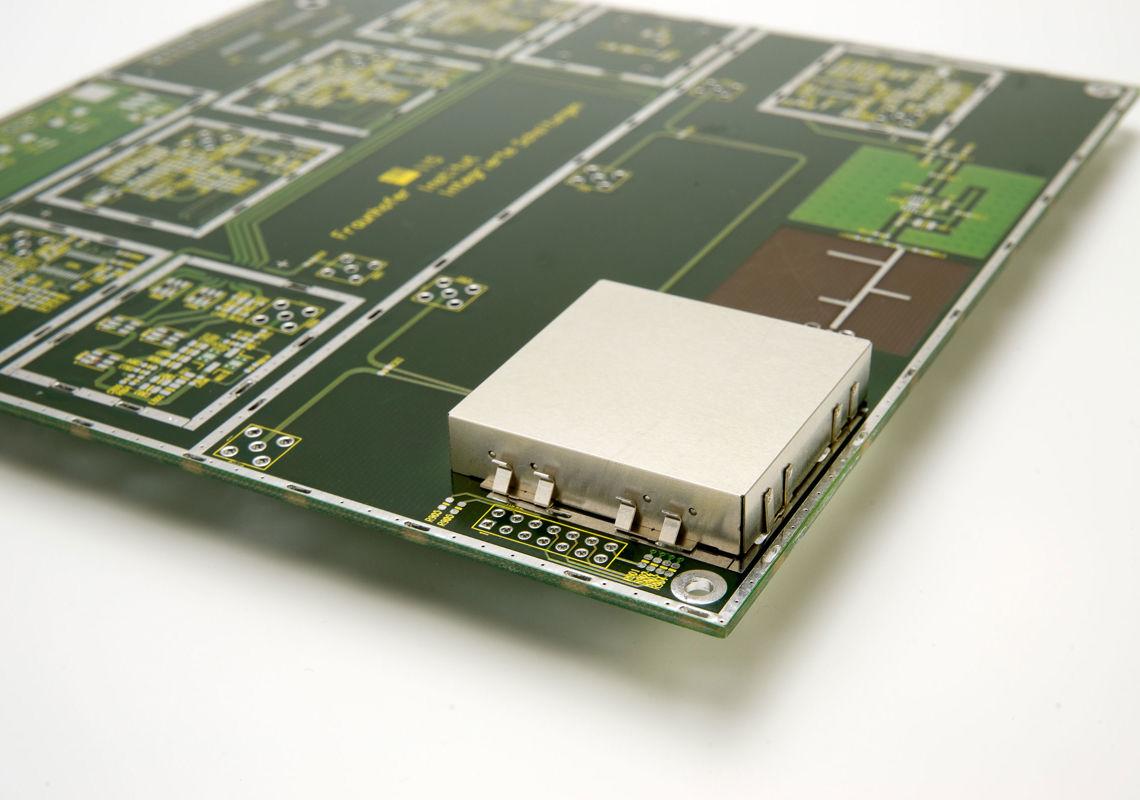

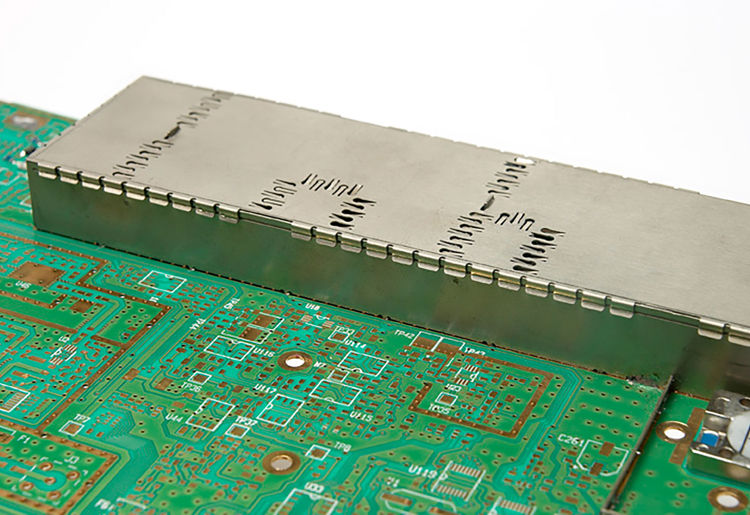

A closed EMI shielding is the ideal solution for protecting electronic components from electromagnetic interference.Closed EMI Shielding

A closed EMI shielding is the ideal solution for protecting electronic components from electromagnetic interference.Closed EMI Shielding -

Our standard EMI shieldings are designed to complement our extensive range of customized solutions.Standard EMI shielding

Our standard EMI shieldings are designed to complement our extensive range of customized solutions.Standard EMI shielding -

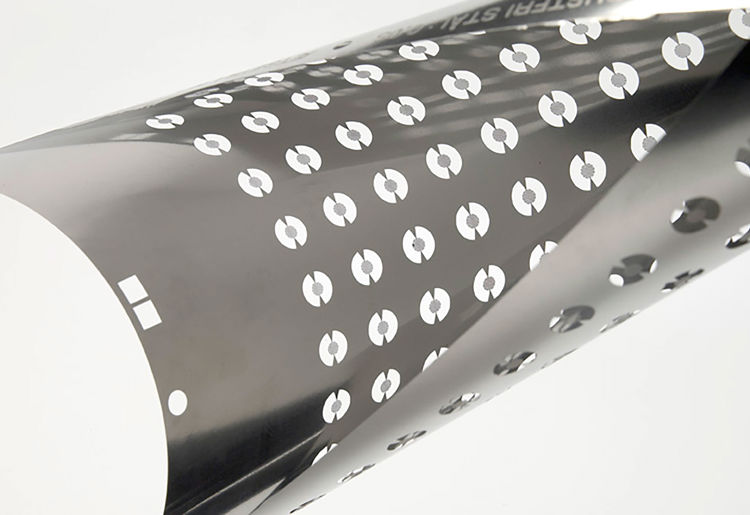

Effective electrical insulation of electronics in your deviceInsulation films

Effective electrical insulation of electronics in your deviceInsulation films