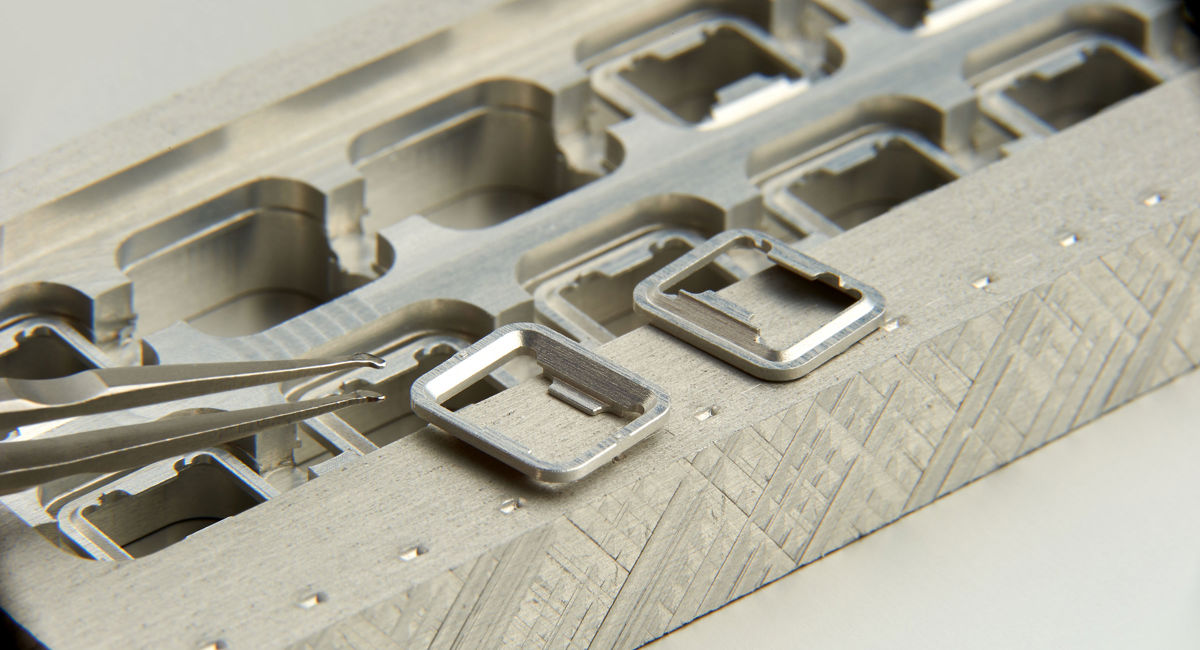

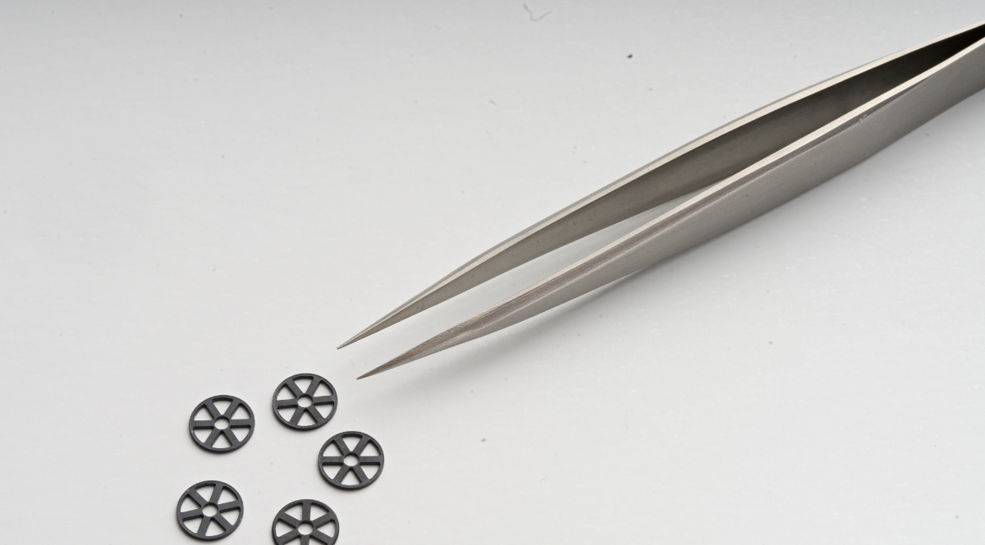

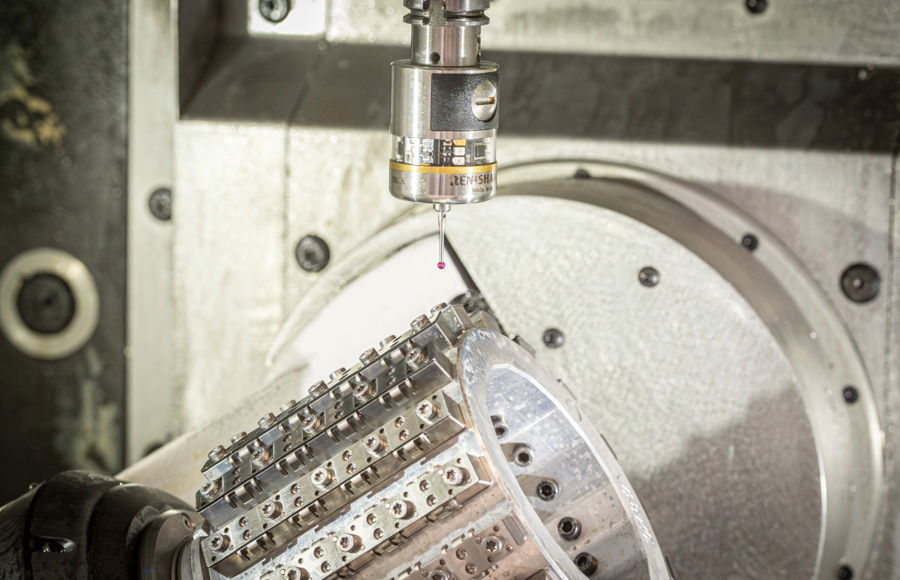

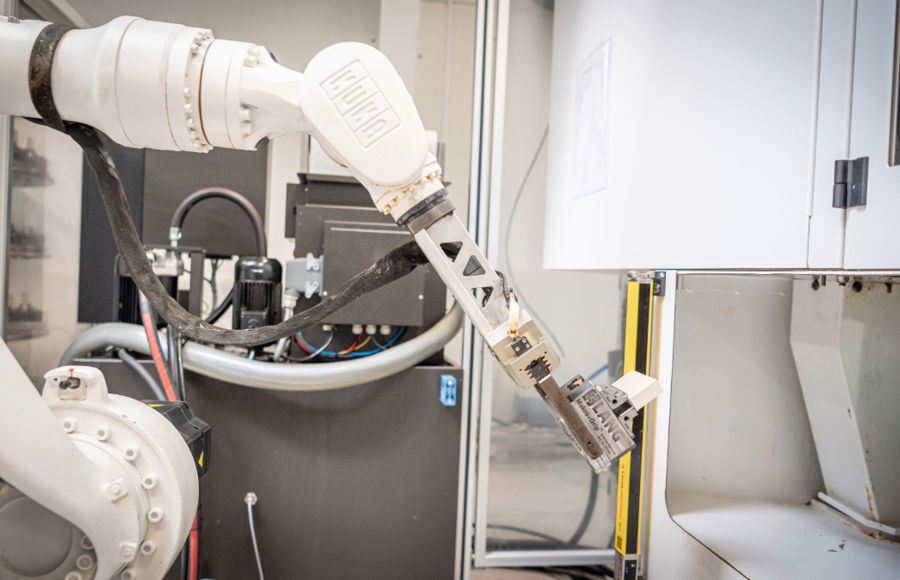

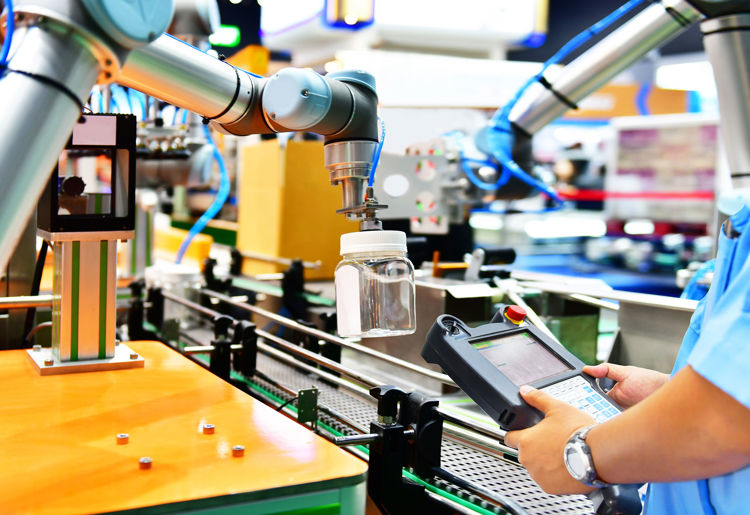

Precise fixturing of complex parts

Fixturing micro-milled components demands high standards for the fixturing method to maintain tight reference chains and geometric specifications. At Mekoprint, we have developed specialized fixturing solutions that enable secure and stable clamping of very small and complex parts.

Optimal fixturing ensures:

-

High repeatability

-

No deformation

-

Minimal manual handling

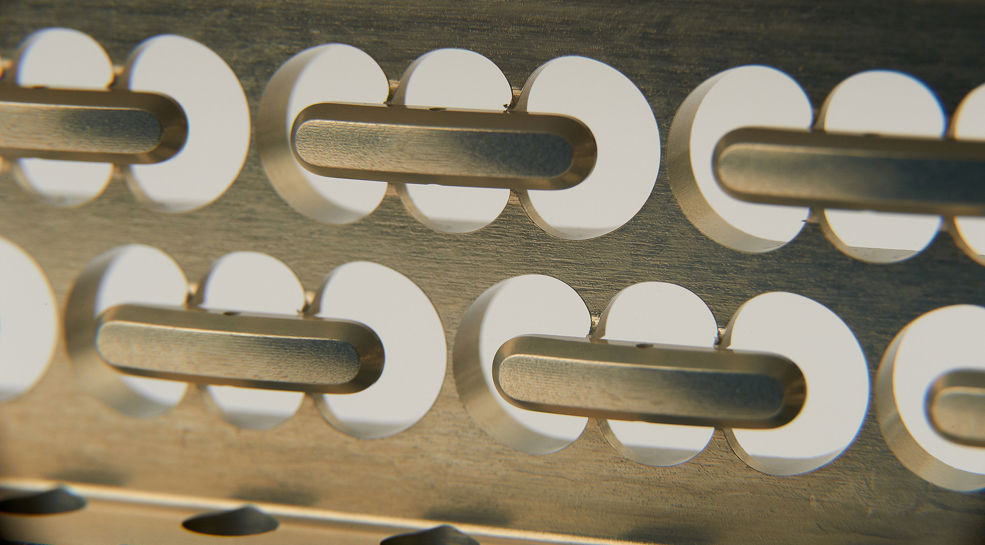

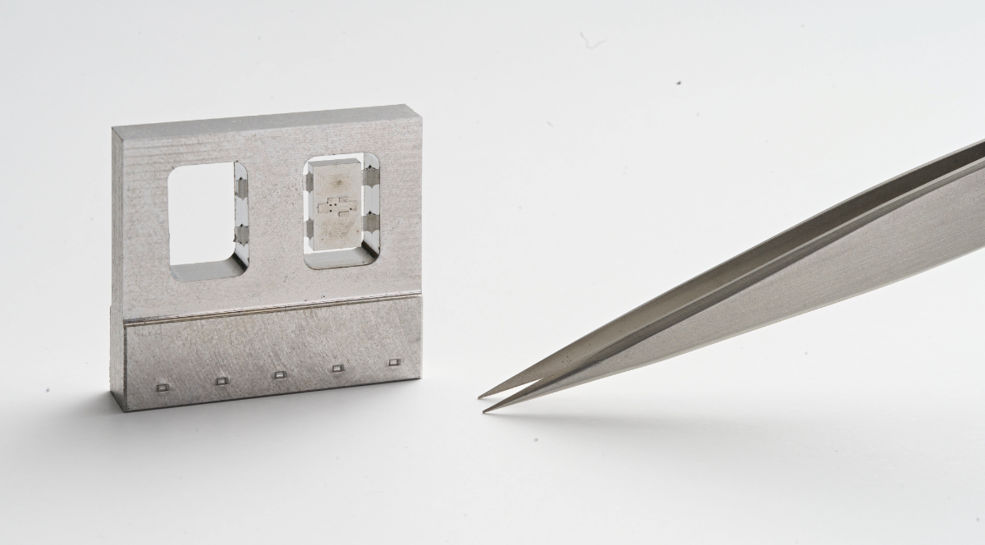

Finish machining in a single setup

With the right techniques, many micro-milled components can be finished in a single setup. This ensures high precision and lower costs—without compromising on quality. At Mekoprint, we are happy to review your part design and advise on potential modifications that can add significant value to your project.

Eliminating a process step improves:

-

Lead time

-

Total cost

-

Tolerances and process variation

-

- Mechanical properties: Aluminium alloys cover a wide range — from easily formable variants to high-strength alloys with excellent mechanical characteristics. This provides great design freedom and the ability to meet both functional and machining requirements.

- Low weight and economy: The low weight combined with good machinability of some alloys makes aluminium an attractive alternative to steel and stainless steel — especially in applications where weight optimization and machining costs are critical.

- Surface treatment: Many aluminium alloys can be surface treated to improve properties such as corrosion resistance, electrical conductivity, solderability, and aesthetics. These treatment options offer great flexibility for the final application.

- Corrosion resistance: Corrosion resistance depends on the alloy’s chemical composition. Many easily machinable aluminium alloys require surface treatment if high durability is needed in demanding environments.

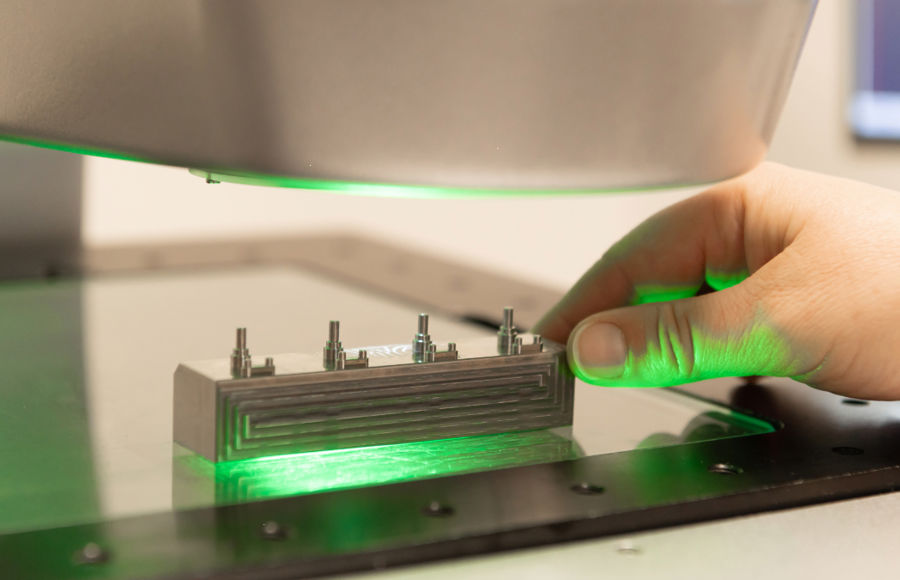

- Thermal conductor: Aluminium has excellent thermal properties and can be used for efficient heat dissipation. This allows, for example, the integration of cooling fins directly into the component design — an advantage in electronics, motor control, and sensor technology.

-

- Thermal stability: PEEK withstands very high operating temperatures while retaining its mechanical properties, making it particularly suitable for applications with thermal stress.

- Chemical resistance: The material is resistant to a wide range of aggressive chemicals, making it well-suited for use in demanding chemical and industrial environments.

- Strength and durability: As a lightweight material with high mechanical strength, PEEK is ideal for precision components where the combination of low weight and robustness is critical.

- Dimensional stability: PEEK has both a low coefficient of thermal expansion and minimal moisture absorption compared to other plastics. This makes the material especially suitable for applications exposed to varying temperatures and humidity levels, where high dimensional stability is essential.

- Material variants: PEEK is available in filled and reinforced versions, which improve wear resistance, electrical conductivity, strength, and coefficient of expansion depending on the requirements of the specific application.

- Medical Grade PEEK: PEEK is available in grades approved for medical device applications and is selected based on the specific application needs.

-

- Chemical resistance: PTFE is extremely resistant to almost all chemicals and is often used in aggressive or corrosive environments where other materials degrade.

- Temperature resistance: The material can be used at high temperatures, making it suitable for thermally stressed applications.

- Low friction: With one of the lowest coefficients of friction among plastics, PTFE is ideal for sliding and sealing elements where minimal wear and smooth movement are desired.

- Electrical insulation: PTFE is an excellent electrical insulator and is used in electronics and other applications.

- Typical applications: PTFE is widely used in the chemical industry, medical devices, electronics, as well as in pumps and valves where the material’s unique properties are advantageous.

-

- Thermal and mechanical stability: Vespel retains its properties at very high temperatures and under significant mechanical stress, making it suitable for use in critical and high-temperature environments.

- Low friction and high wear resistance: The material has low friction and high wear resistance, making it ideal for moving components requiring long service life and operational reliability.

- Dimensional stability: Even under extreme conditions, Vespel remains dimensionally stable and precise — a crucial characteristic for precision applications with tight tolerances.

- Typical applications: Vespel is commonly used for precision bearings, bushings, insulators, and other components where mechanical robustness and heat resistance are essential.

- Industries: The material is employed in demanding industries such as aerospace, automotive, and advanced electronics, where conventional plastics are insufficient.

Want to learn more?

Are you unsure if micro-milling is the right solution for your project? Contact us for a technical assessment and consultation—whether you are in the idea phase or ready to start production.

Get in touch with us

-

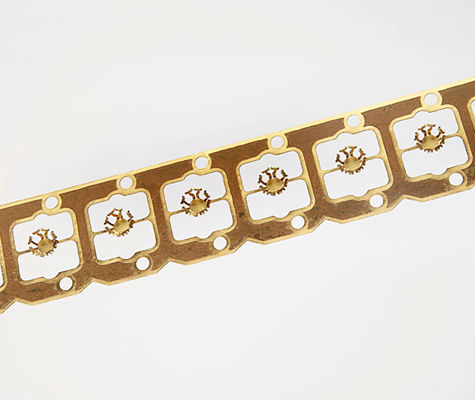

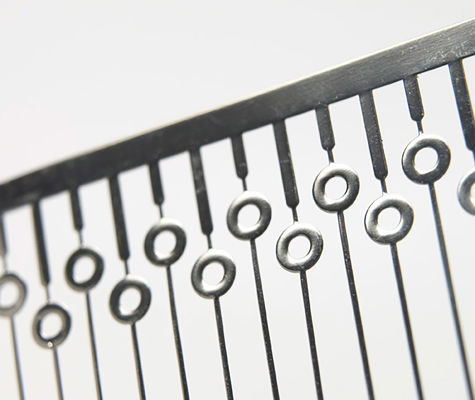

Experience precision like never before with our team of skilled experts crafting micro sheet metal parts.Micro sheet metal parts

Experience precision like never before with our team of skilled experts crafting micro sheet metal parts.Micro sheet metal parts -

Explore the wide variety of micro component solutions tailored to your needs.Precision Micro Components

Explore the wide variety of micro component solutions tailored to your needs.Precision Micro Components -

Our custom milling services are designed to meet your exact specifications, ensuring high-quality, efficient production for any project size.Milled solutions

Our custom milling services are designed to meet your exact specifications, ensuring high-quality, efficient production for any project size.Milled solutions