Testing and Quality Control for Maximum Precision

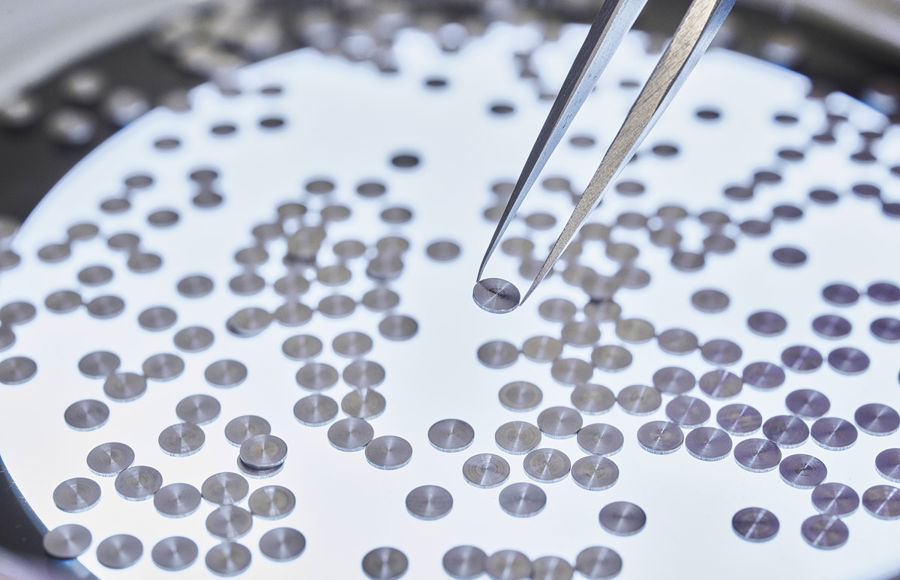

As part of our service, we conduct thorough testing and quality control of all micro-turned components, carefully tailored to the customer's needs. We utilize microscopic inspection and advanced measurement methods to ensure that the components meet the stringent tolerances and requirements set by our customers. Each month, we perform visual inspection and microscopic inspection of over 2 million components to ensure consistently high quality.

Quality and Delivery Reliability – We Deliver on Time

Quality and Reliable Delivery

Mekoprint Microturn is known for its reliability, and we do not compromise on quality. In 2024, we had a deviation rate of less than 0.5%, demonstrating our dedication to delivering products that adhere to agreed specifications and deadlines. Our advanced production system and quality control methods ensure that your micro components are delivered exactly as promised.

Documentation and Certifications

To ensure the highest quality and delivery reliability, we offer detailed documentation and audits as needed. We can provide certificates and inspections that meet the specific requirements of both national and international standards.

Get in touch with us

-

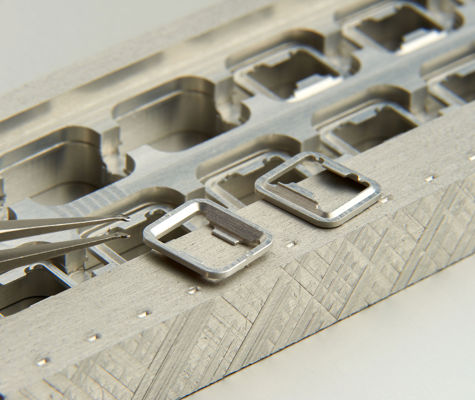

We are specialists in manufacturing micro-milled components for applications where precision and reliability are critical.Micro-milled components

We are specialists in manufacturing micro-milled components for applications where precision and reliability are critical.Micro-milled components -

We offer specialist expertise in micro component solutions and additional resources to ensure your project's progress.Design & engineering of micro solutions

We offer specialist expertise in micro component solutions and additional resources to ensure your project's progress.Design & engineering of micro solutions -

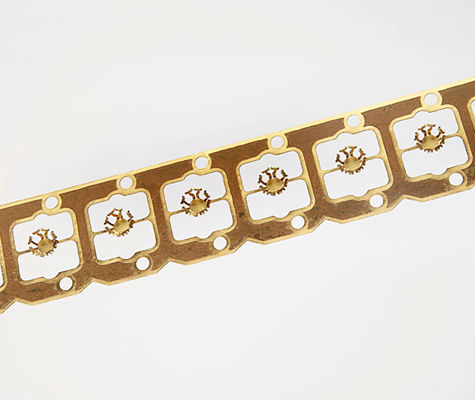

Experience precision like never before with our team of skilled experts crafting micro sheet metal parts.Micro sheet metal parts

Experience precision like never before with our team of skilled experts crafting micro sheet metal parts.Micro sheet metal parts