Explore the evolving possibilities of printed electronics

Our focal point is to make printed electronics components that fit your final application perfectly. At Mekoprint we develop and manufacture customised printed sensors and circuits for a wide variety of industries. We have been doing this for decades.

The opportunities in printed electronics have grown a lot in recent years, and together we are continually pushing the boundaries even further.

-

Cost-efficient, lightweight, and flexible user interfaces in applications where touch operation is preferred.Capacitive touch sensors

Cost-efficient, lightweight, and flexible user interfaces in applications where touch operation is preferred.Capacitive touch sensors -

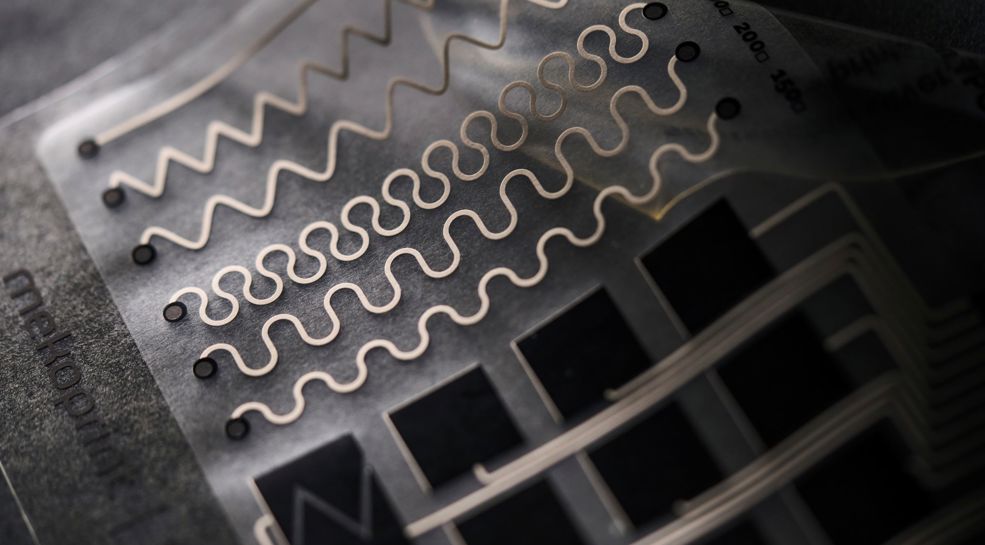

Ultra-thin wearable sensors ideal for single-use health care applications. Brings electronics close to the body.Wearable sensors

Ultra-thin wearable sensors ideal for single-use health care applications. Brings electronics close to the body.Wearable sensors -

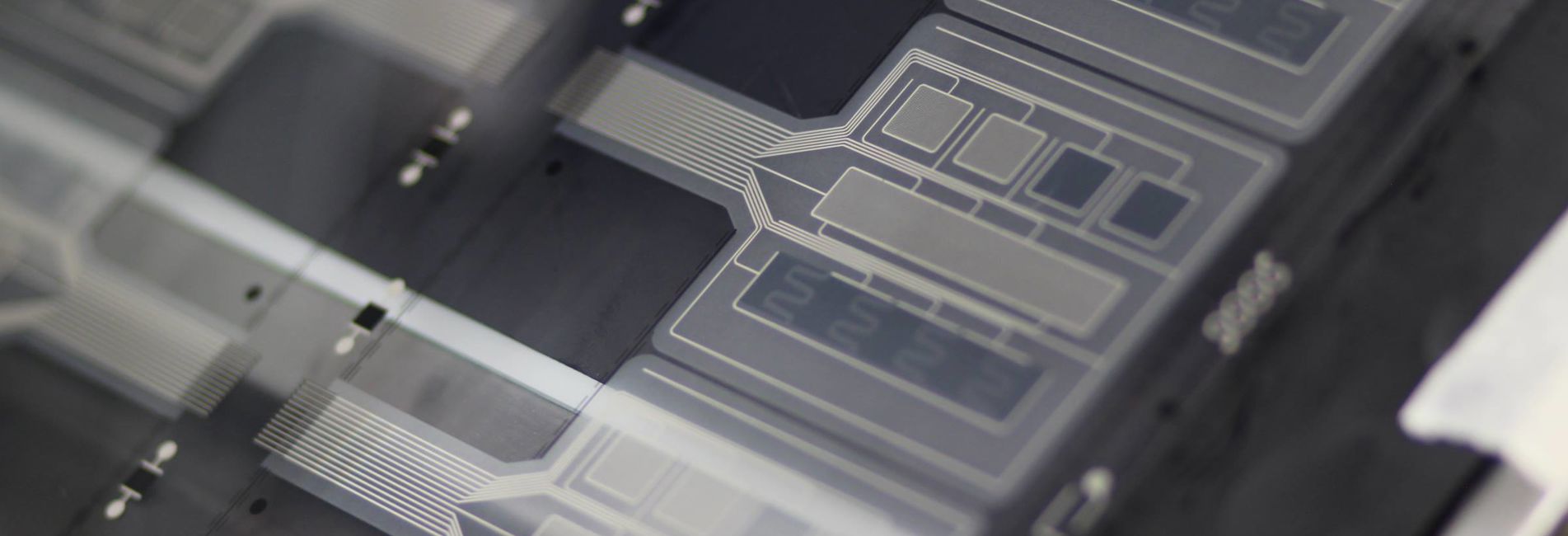

Flexible circuits cut down on space and weight. Ideal for devices where a rigid circuit board will be impractical.Flexible circuits

Flexible circuits cut down on space and weight. Ideal for devices where a rigid circuit board will be impractical.Flexible circuits -

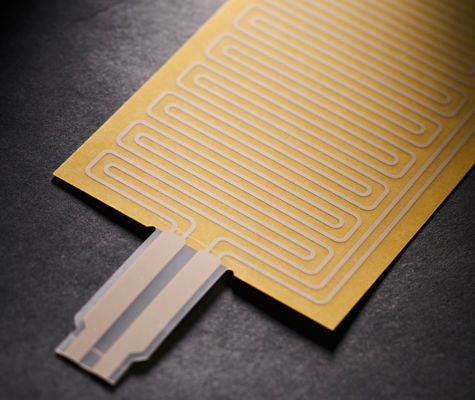

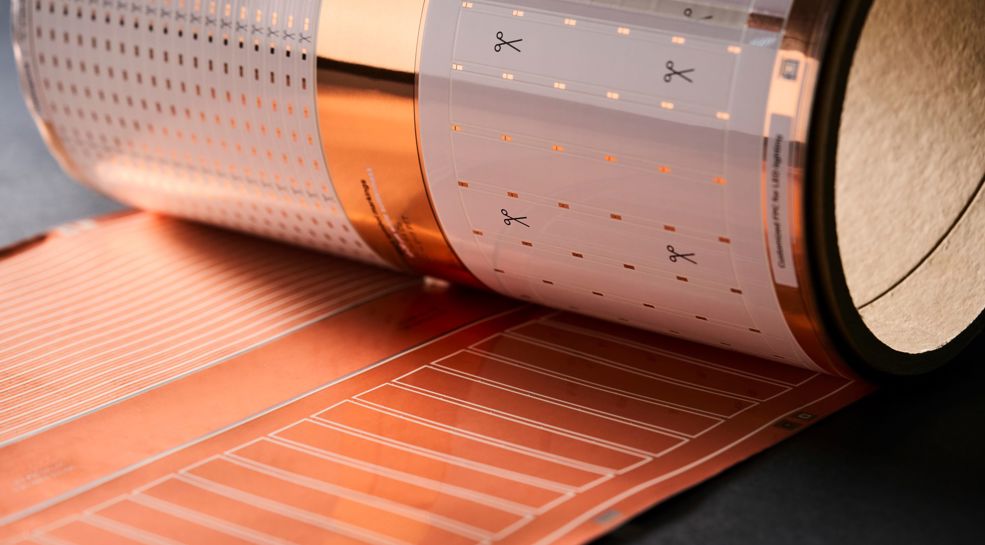

Lightweight and thin printed heaters. Flexible structure, easy to integrate and tailored to any shape and size.Printed heaters

Lightweight and thin printed heaters. Flexible structure, easy to integrate and tailored to any shape and size.Printed heaters

Get in touch with us

Building blocks of printed electronics

-

The core of all printed electronics begins with the right choice of conductive inks. The choice is based on the needed level of functionality, quality, and price.

At Mekoprint you can benefit from a number of already tested and proven inks. Or we will assist in finding new and adapted inks to fit your specific application.

-

When using printed electronics as a key component in your application, it is important to consider properties of the substrates.

You will have to choose from a number of features, as different materials support components thickness, light diffusion, weight, bendability, stretchability, and more.

-

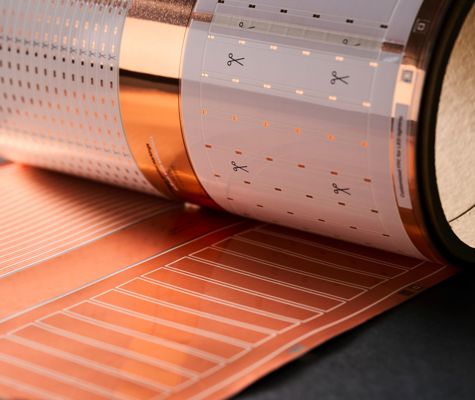

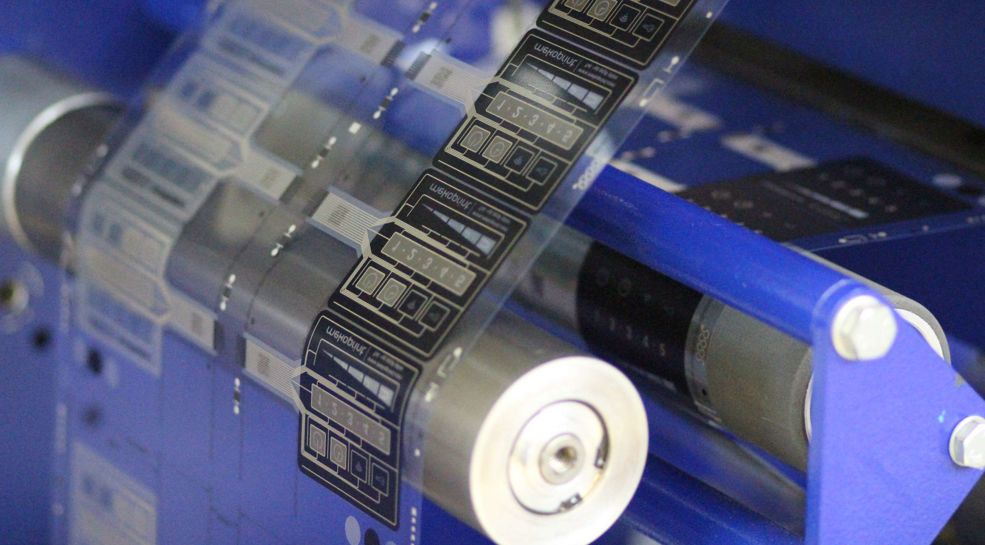

Roll-to-roll screen printing is perfect for mass production of printed electronics. The technology allows high automation enabling lower costs and high uniform quality. As well as the ability to make complex structures with exact precision.

Together we will choose the right manufacturing method to suit your project.

-

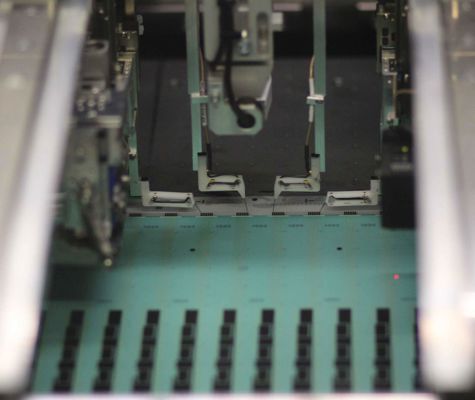

Printed electronics are pushing the limits for electrical components by being smaller, thinner, and even transparent at a level where the human eye cannot detect errors.

At Mekoprint we have developed electrical test systems and automated optical inspection to ensure that only functional components are shipped to your factory.

-

Download our lookbook for an insight to technology, building blocks, use cases, industry trends, and more inspiration.Printed electronics lookbook

Download our lookbook for an insight to technology, building blocks, use cases, industry trends, and more inspiration.Printed electronics lookbook -

Watch our short webinars about printed electronicsWatch Printed Electronics webinars

Watch our short webinars about printed electronicsWatch Printed Electronics webinars -

Order a printed electronic sensor sample to make your process easier and more efficientOrder printed sensor sample

Order a printed electronic sensor sample to make your process easier and more efficientOrder printed sensor sample

Download free lookbook

-

Development, production maturation, and large-scale production in collaboration with our engineering team.Engineering printed electronics

Development, production maturation, and large-scale production in collaboration with our engineering team.Engineering printed electronics -

Automated manufacturing of large-scale printed electronic sensors and circuits with uniform design.Production of printed electronics

Automated manufacturing of large-scale printed electronic sensors and circuits with uniform design.Production of printed electronics -

Automated electrical function test of printed electronic components on rolls. Tailored to each individual project.Test of printed electronics

Automated electrical function test of printed electronic components on rolls. Tailored to each individual project.Test of printed electronics