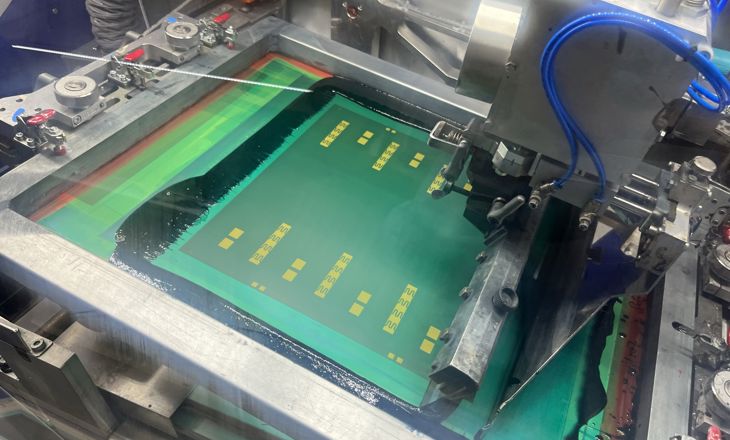

Engineering printed electronics

Our team of engineers specialised in printed electronics is your go-to for everything within product development, production maturation, and high volume production.

No matter how your process unfolds, we will support you and strive to make a difference in the success of your solution. We will never work according to our own agenda but allow ourselves to challenge you on new and alternative solutions that contribute to your development, operation and position in the market.

- The straightforward track

Represents projects where materials and processes are known in Mekoprint's production. We call this our fast track, as this is often business-as-usual..

- The research trails

Represents projects where materials and processes are untried in Mekoprint's production. Here, extra loops will be needed to verify choices and approach, before moving on to the next step.

Whether you are creating something new or finding ways to optimise an already exiting product with new electronics, you are probably seeking inspiration and gathering information supporting your future possibilities.

With us, you choose the level of involvement. We can assist you in every step of the way, or you can draw on our engineering team and development services to the extent your project needs.

Choose the right level of collaboration in your project with our engineering services

-

By sharing and exchanging knowledge in close and confidential cooperation we lay the groundwork for the project and our future work together.

With the discovery phase we will explore specifications and scope of the project to align our level of collaboration.

-

If the solution requires either new materials or new untried functionality, we will explore and review various directions to verify and lift your project from idea to a proven concept.

At this stage, we will decide the direction for product design and material composition.

-

With clear and well-defined functions, materials, and no unknown factors regarding to the overall design, we will begin to engineer the product.

In this phase we will finalise product design, material stack, tolerances, and test specifications, keeping in mind the final full-scale production.

-

If the project requires adaption of manufacturing technology or new materials, we will conduct the required number of feasibility studies of material behaviour through all manufacturing processes.

In this phase we will demonstrate production processes and methods.

-

When engineering for production, we align all the elements, prepare for series production, and release to full-scale-production after approved 0-series.

We work out the optimal supply chain and logistics setup accordingly. Documentation related to process, materials, and quality are also processed.

-

If the current manufacturing setup does not match the product or business case, we will look into possible investments in new manufacturing technology together.

Activities in this phase will support decision making from research of opportunities to plan for implementation.

-

Life-cycle engineering covers a long list of services designed to keep your product successful throughout its lifetime, ensuring your peace of mind until the products 'end-of-life'.

Get in touch with us

Head of Printed Electronics

Tobias Holmgaard Stær

-

Download our lookbook for an insight to technology, building blocks, use cases, industry trends, and more inspiration.Printed electronics lookbook

Download our lookbook for an insight to technology, building blocks, use cases, industry trends, and more inspiration.Printed electronics lookbook -

Watch our short webinars about printed electronicsWatch Printed Electronics webinars

Watch our short webinars about printed electronicsWatch Printed Electronics webinars -

Order a printed electronic sensor sample to make your process easier and more efficientOrder printed sensor sample

Order a printed electronic sensor sample to make your process easier and more efficientOrder printed sensor sample

Download free lookbook

-

Cost-efficient, lightweight, and flexible user interfaces in applications where touch operation is preferred.Capacitive touch sensors

Cost-efficient, lightweight, and flexible user interfaces in applications where touch operation is preferred.Capacitive touch sensors -

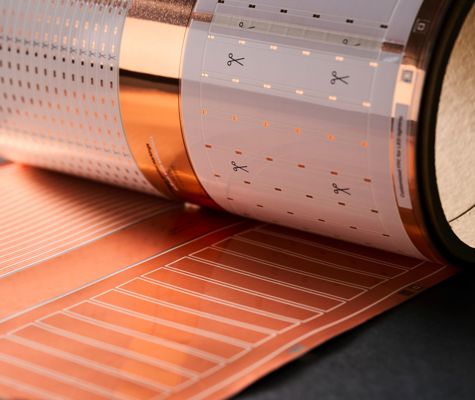

Ultra-thin wearable sensors ideal for single-use health care applications. Brings electronics close to the body.Wearable sensors

Ultra-thin wearable sensors ideal for single-use health care applications. Brings electronics close to the body.Wearable sensors -

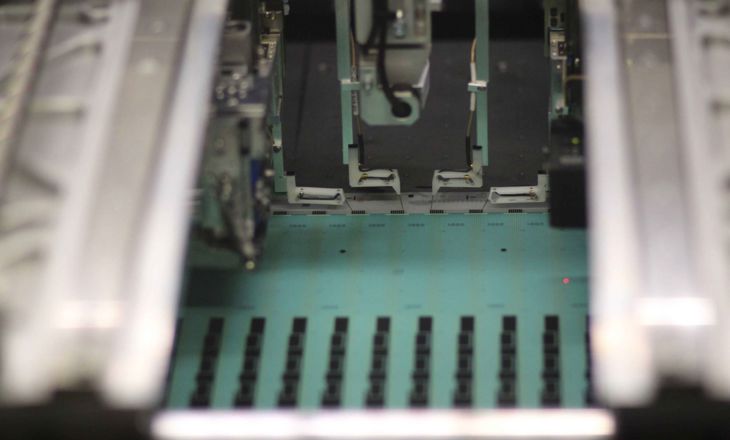

Flexible circuits cut down on space and weight. Ideal for devices where a rigid circuit board will be impractical.Flexible circuits

Flexible circuits cut down on space and weight. Ideal for devices where a rigid circuit board will be impractical.Flexible circuits