Customised test options

-

Testing the ability of a component to store an electrical charge. This test is essential for assessing the performance of capacitors and circuits that rely on capacitive elements.

Accurate measurement helps ensure stability and functionality in electronic devices.

-

Determines how much a material or component opposes the flow of electric current. It's crucial for verifying the electrical integrity and specifications of resistors and conductive paths.

Consistent resistance levels are key to device reliability.

-

Testing the ability of a component to induce a voltage as a result of a changing current.

Influencing how effectively the component can manage current changes in circuit applications.

-

Detecting interruptions in electrical traces.

Essential to ensure there are no breaks that could disrupt the electrical continuity and affect the performance of electronic circuits.

-

Identifies unwanted connections between conductive traces that should be isolated.

-

Checking individual electronic parts for functionality and compliance with technical specifications.

Head of Printed Electronics

Tobias Holmgaard Stær

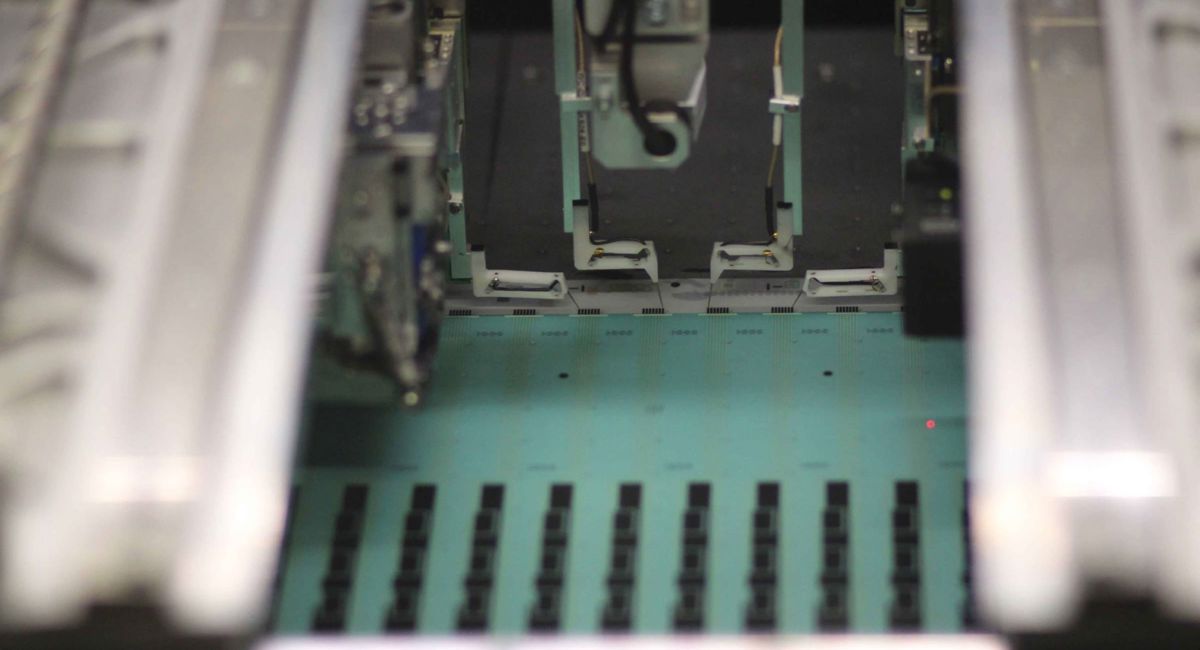

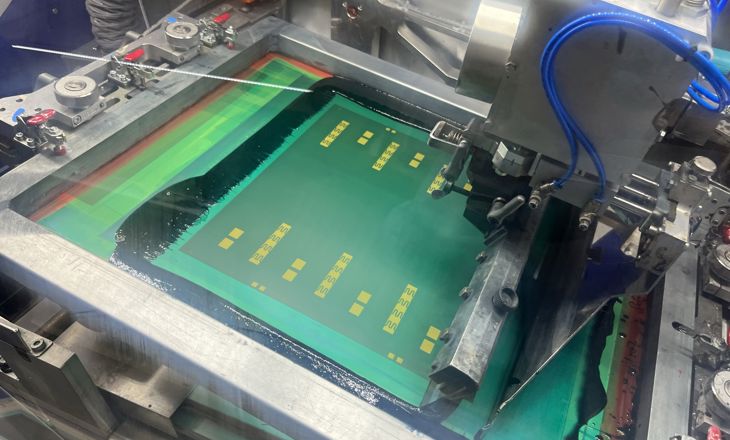

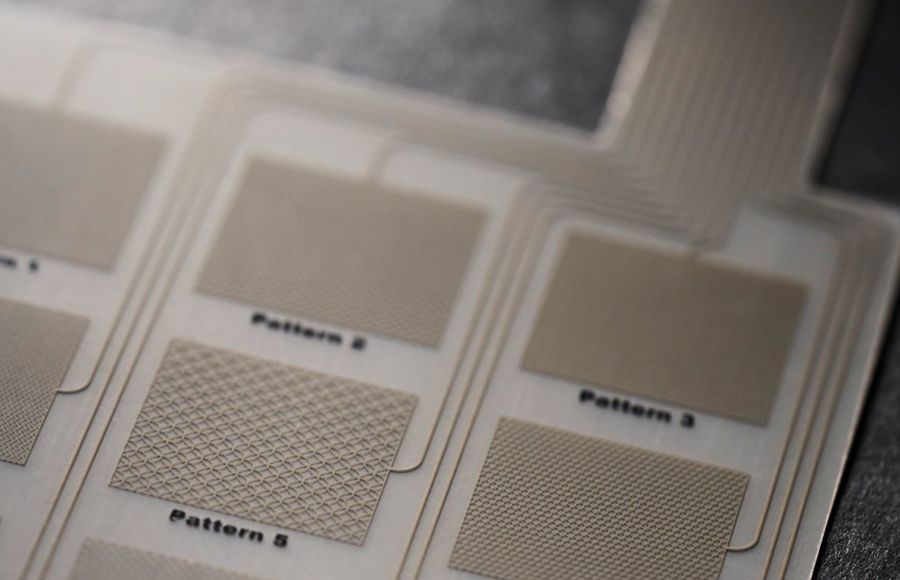

Increasingly complex printed solutions

The growing use of printed electronics technology across consumer products, industrial machinery, wearable technology, and other industries, means increased attention on our capabilities.

During recent years we have experienced a shift from simple solutions to more complex solutions. Fine line conductive traces, and materials with flexible and stretchable features has boosted the need.

Advanced solutions incorporating high levels of detail requires precise process control.

Our test procedure eliminates uncertainty, and guarantee a thoroughly-tested printed electrical component. Ready for in-line, high volume production and at a competitive price.

A number of our customers have already benefited enormously. Are you interested in further dialogue on how we can assist in your project?

-

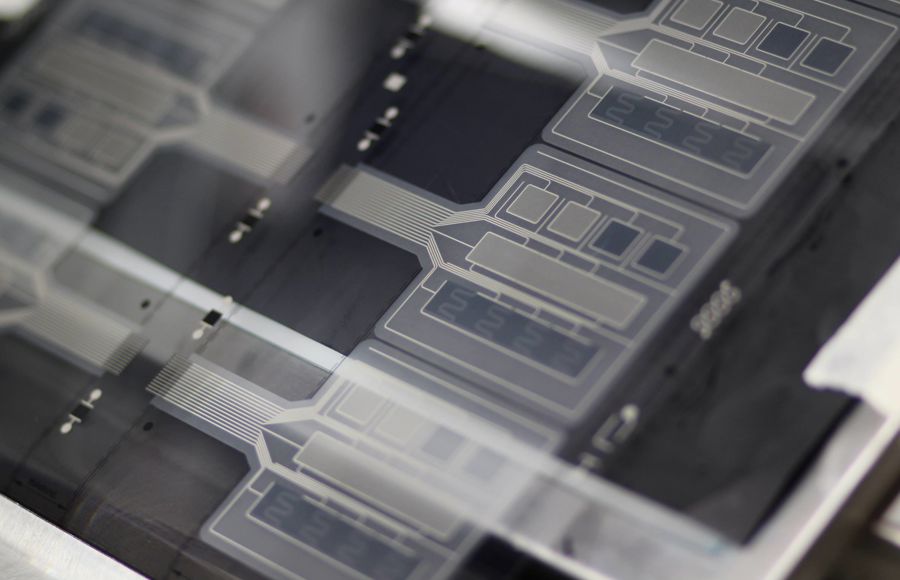

Cost-efficient, lightweight, and flexible user interfaces in applications where touch operation is preferred.Capacitive touch sensors

Cost-efficient, lightweight, and flexible user interfaces in applications where touch operation is preferred.Capacitive touch sensors -

Ultra-thin wearable sensors ideal for single-use health care applications. Brings electronics close to the body.Wearable sensors

Ultra-thin wearable sensors ideal for single-use health care applications. Brings electronics close to the body.Wearable sensors -

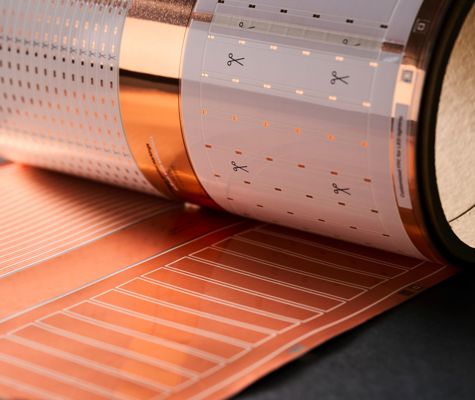

Flexible circuits cut down on space and weight. Ideal for devices where a rigid circuit board will be impractical.Flexible circuits

Flexible circuits cut down on space and weight. Ideal for devices where a rigid circuit board will be impractical.Flexible circuits