Precision Sheet Metal Experts: From Design to Production

At Mekoprint, our extensive experience spans consulting, development, and precision sheet metal production. Our team of skilled experts can serve as your partner, offering guidance from design and development to series production.

We are available throughout the process to recommend the optimal manufacturing technology, including etching, punching, bending, laser-cutting and laser welding. With a strong focus and track record in delivering precision sheet metal solutions, we specialize in serving the electronics and medical industries.

Order a free sample of micro parts

Why choose Mekoprint? Let's brake it down

-

We offer design and development expertise to support you in the production of your micro sheet metal component. From initial idea and concept development to construction, we provide guidance on component refinement for production, offering support through prototyping to full-scale production.

-

We manufacture precision metal sheet components in a variety of materials, including stainless steel, aluminum, brass, copper, and others, based on your specific requirements and preferences.

-

Our extensive range of technologies allows us to integrate various processes, including etching, bending, punching, stamping, laser cutting, and laser welding, to create customized solutions that meet your specific needs and requirements.

-

We offer an extensive array of surface treatments for micro sheet metal components such as anodizing, powder coating, wet coating, and SurTec 650, performed in-house and other surface treatments through our trusted network of partners.

-

We employ various measurement technologies, including video measuring system for quality control of our micro metal sheet components. Through documentation, we ensure the accuracy of each component, guaranteeing that our delivered product meets all your specified requirements, including precise measurements and geometries of superior quality. If required, fully documented measurement reports can be delivered on even the most complex parts.

Discover our broad range of technology processes

-

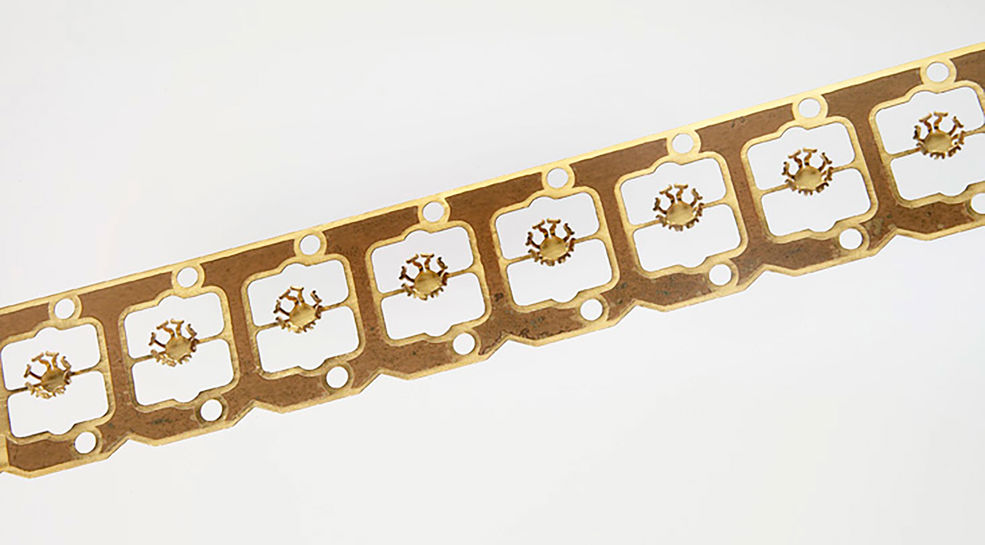

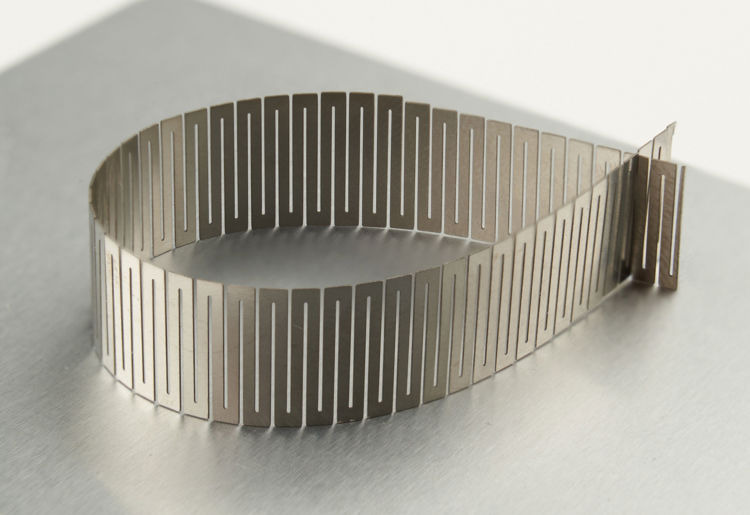

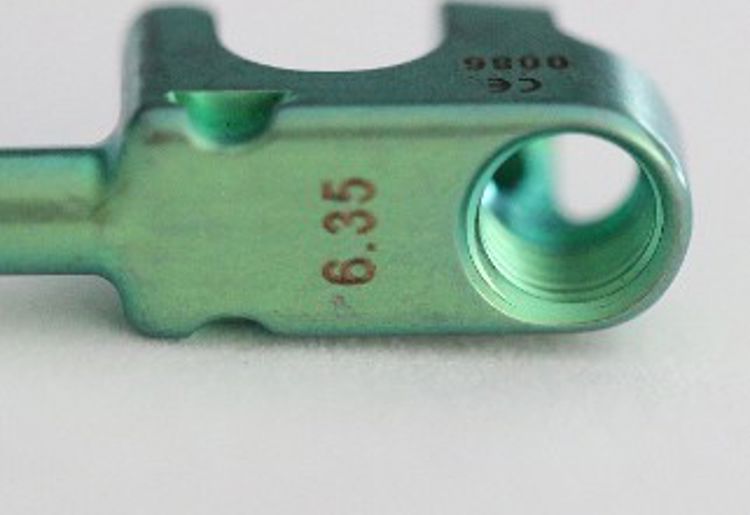

The etching process allows for the production of highly complex components with geometries and tolerances +/-0,03 mm that traditional mechanical sheet metal manufacturing cannot achieve. We offer high capacities, no tool cost and material thicknesses up to 1,0 mm. Furthermore, the process produces completely tension and burr-free components.

-

-

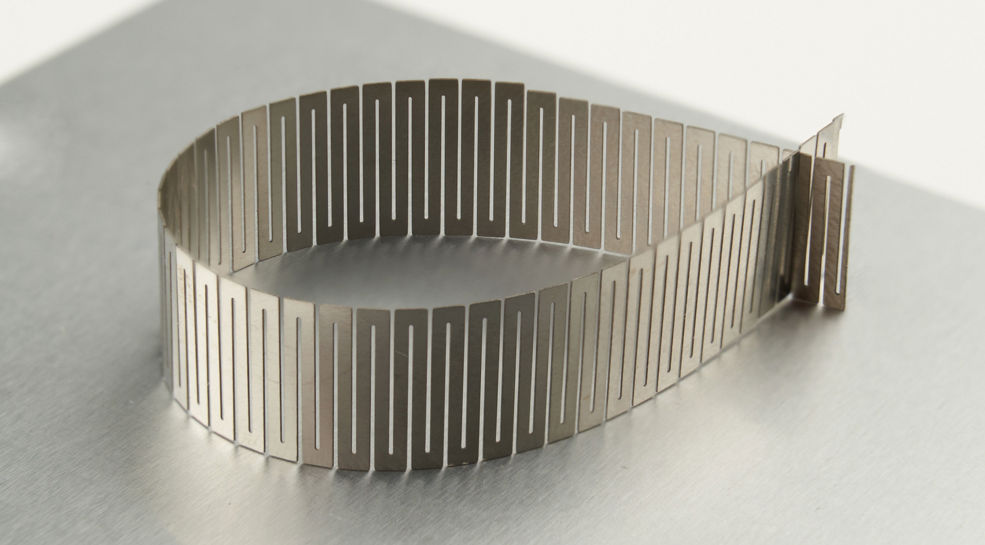

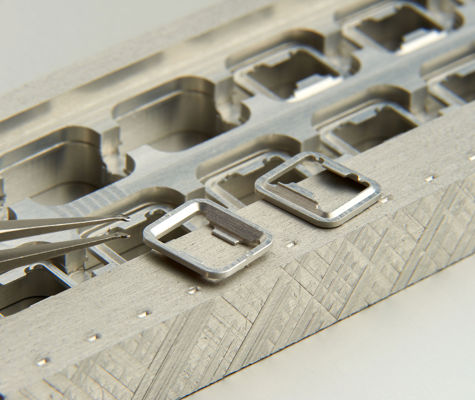

In our custom sheet metal stamping process from coils, we manufacture from low to high-volume stamped parts using progressive die stamping technology. This process enables us to stamp, bend, and cut threads, making it highly competitive and efficient for producing stamped and deep-drawn sheet metal components.

-

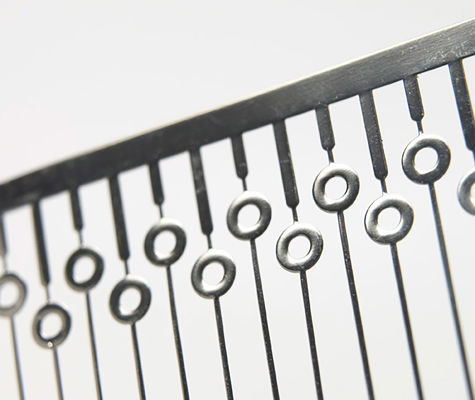

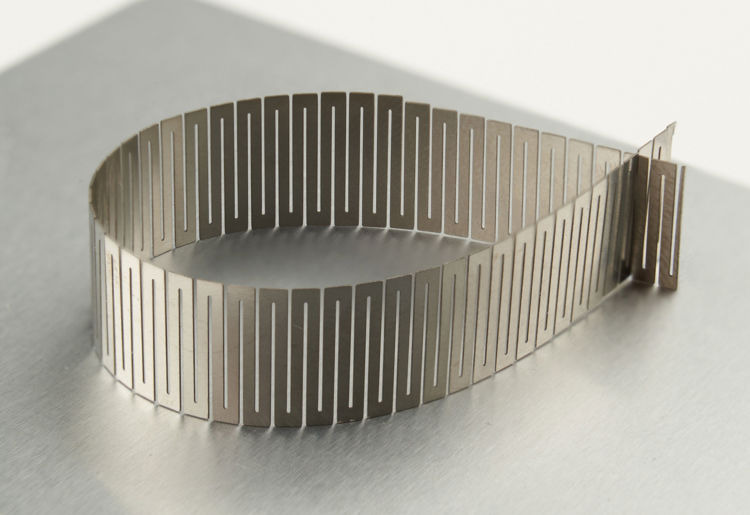

We offer laser cutting of micro-sheet metal components, which can be combined with our welding technology. This method is suitable for designs requiring extremely high geometric precision or very narrow tracks relative to material thickness, ranging from 0.05 mm to 1.5 mm, with tolerances of +/-0.01 mm.

-

Laser welding is a fast and efficient method for joining two metals with minimal heat impact, resulting in a uniform finish on the workpiece without the need for additional processing.

-

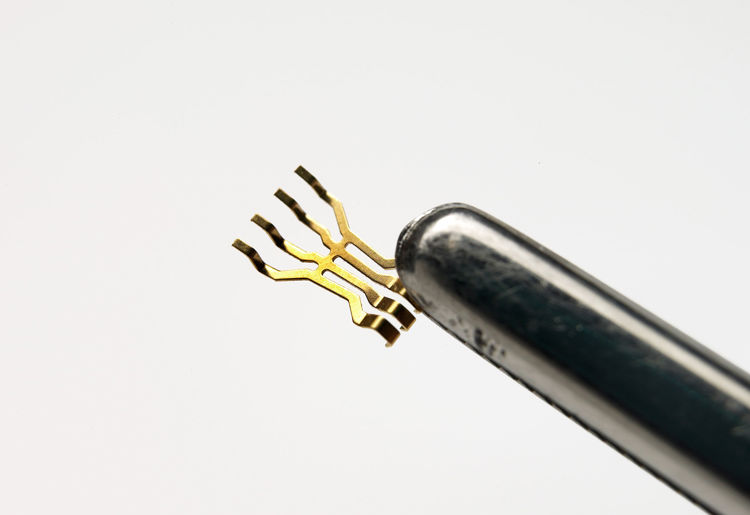

Laser engraving and marking provide unique identification and traceability in demanding industries. We offer engraving services for components with complex geometries, including text and graphics such as logos. The process is fast and efficient.

Get in touch with us

-

Explore the wide variety of micro component solutions tailored to your needs.Precision Micro Components

Explore the wide variety of micro component solutions tailored to your needs.Precision Micro Components -

We are specialists in manufacturing micro-milled components for applications where precision and reliability are critical.Micro-milled components

We are specialists in manufacturing micro-milled components for applications where precision and reliability are critical.Micro-milled components -

We offer specialist expertise in micro component solutions and additional resources to ensure your project's progress.Design & engineering of micro solutions

We offer specialist expertise in micro component solutions and additional resources to ensure your project's progress.Design & engineering of micro solutions