-

We believe in laying a strong foundation before starting any outsourcing project. By working closely together, we outline the products involved and establish a comprehensive schedule, diving into technical specifications, quality standards, and existing agreements with component distributors to ensure transparency.

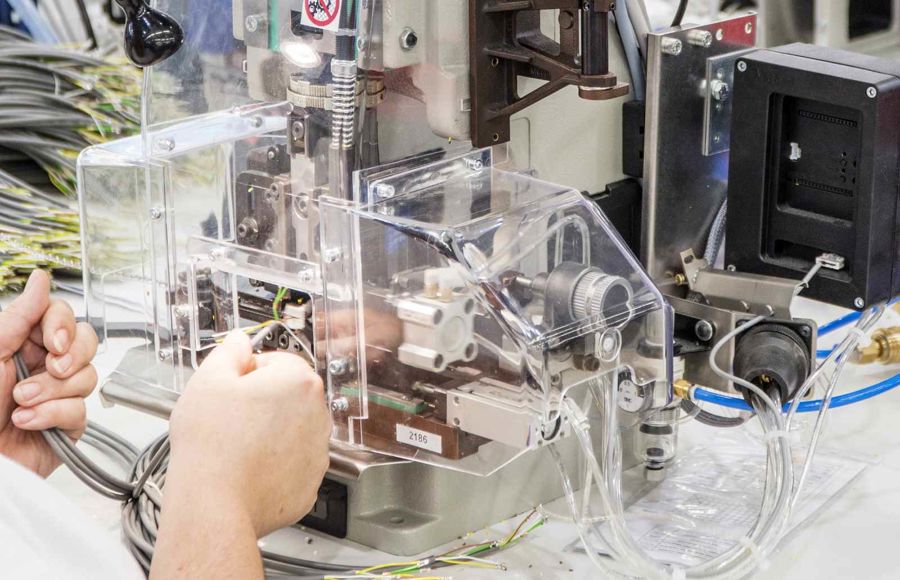

We will of cause invite you to visit our production facility to see our setup and quality management system (QMS) firsthand.

-

Choosing us as your cable assembly supplier unlocks various options tailored to your needs, from flexible framework agreements to customised logistics setups, including Vendor Managed Inventory (VMI) warehouse solutions.

We specialise in industries like green tech, industrial automation, automotive, and medical and provide essential documentation such as Production Part Approval Process (PPAP), First Article Inspection Report (FAIR), and Part Submission Warrant (PSW), alongside sample production.

Our commitment to quality is highlighted by our ISO 9001, 14001, and 45001 certifications, along with adherence to IPC/WHMA-620 standards.

-

As we move into the delivery phase, we maintain close collaboration to set up comprehensive trading, logistics, and quality agreements that ensure smooth operations.

We will strictly follow agreed schedules, forecasts, or orders and optimise our automated production for efficiency.

Drawing from our track record of successful outsourcing projects with industry leaders like Siemens, Danfoss Drives, and SMA Solar, we are ready to discuss any outsourcing project or related inquiries you may have.

-

Heavy cables with thick insulation and robust conductors built to endure high electrical currents and mechanical stress.Heavy cables

Heavy cables with thick insulation and robust conductors built to endure high electrical currents and mechanical stress.Heavy cables -

Organised bundles of wires, connectors, terminals and protective sheaths. Simple or complex assembly.Wiring harness

Organised bundles of wires, connectors, terminals and protective sheaths. Simple or complex assembly.Wiring harness -

Molded connectors, housings, or overmolds ensure optimal performance and durability in various environments.Molded cables

Molded connectors, housings, or overmolds ensure optimal performance and durability in various environments.Molded cables